[Introduction]: Leaching agitation tank is a leaching equipment for cyanide leaching by referring to the USA technical design.

[Capacity]: 6-395m³

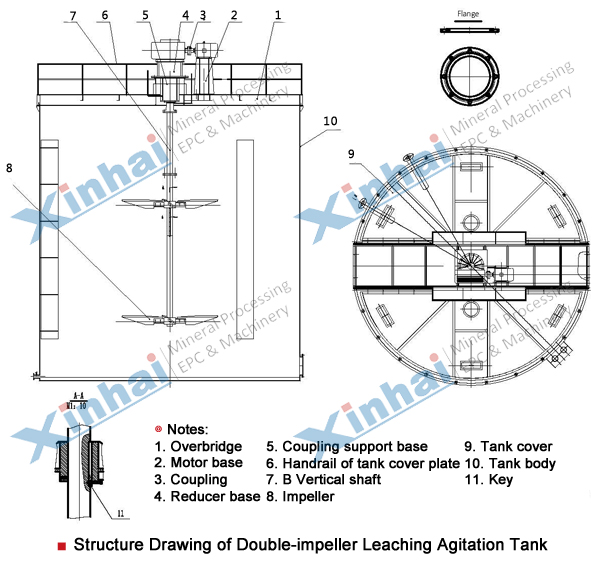

[Improvement]: Leaching agitation tank for gold extraction is improved with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to supply with the gas, uniform inflation.

The impeller of this leaching tank is lined with wear-resistant rubber, low rotation speed, and long service life.

Moderate agitation intensity, and uniformly distributed in pulp concentration and fineness, which can improve the leaching rate of cyanidation and the adsorption rate of carbon;

Adopt two new impellers, the agitation tank is featured with a large impeller diameter, low rotation speed, small power consumption, which can reduce the wear of carbon;

The air enters the tank through the transmission hollow shaft, and the air disperses evenly with the blade agitation;

Smooth movement of ore flow, even pulp mixture, less power consumption;

Compact structure, easy to maintain;

Hollow shaft is ventilated to the bottom end, and the air enters into the tank with uniform distribution and small bubbles;

With dual impellers rotating and agitating, ore pulps move downward and then diffuse along with the damping plate. Air is fed in the tank from the lower end of the shaft and blended with ore pulps to form a uniform suspending mixed liquid.

In the gold cyaniding process, a leaching agitation tank is applied to leach and carbon-absorb ore pulps whose fineness is -200 meshes and whose density is less than 45%. Under similar circumstances, it is also applied to agitation and leaching in metallurgy, chemical, and light industry.

| Model | Tank Spec. (DX H) (mm) | Effective Volume (m3) | Rotating Speed of Impeller (r/min) | Diameter of Impeller (mm) | Motor Model | Motor Power (kW) | Reducer Model | Tank Weight (kg) | Total Weight (kg) |

| SJ2.0X2.5 | 2000X2500 | 7.07 | 52 | 909 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5X2.5 | 2500X2500 | 10.8 | 43 | 935 | Y112M-4 | 4 | XLD4-5-35 | 2159 | 2729 |

| SJ2.5X3.15 | 2500X3150 | 13.92 | 52 | 935 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 2398 | 3095 |

| SJ3.0X3.0 | 3000X3000 | 19 | 43 | 1130 | Y112M-4 | 4 | XLD4-5-35 | 3480 | 4583 |

| SJ3X3.15 | 3000X3150 | 20 | 3480 | 4160.6 | |||||

| SJ3X3.5 | 3000X3500 | 22.97 | 3211 | 4334.6 | |||||

| SJ3.15X3.55 | 3150X3550 | 25.73 | 1260 | 3433.5 | 4322.8 | ||||

| SJ3.5X3.5 | 3500X3500 | 31.3 | 52 | 1310 | Y132S-4 | 5.5 | XLD5.5-5-29 | 3480 | 5025 |

| SJ3.5X4 | 3500X4000 | 35.6 | 4230 | 5429 | |||||

| SJ3.55X4.0 | 3550X4000 | 36.8 | 43 | 4 | XLD4-5-35 | 4260 | 5025 | ||

| SJ3.7X4.2 | 3700X4200 | 42 | 42 | Y112M-4 | XLD4-5-43 | 5266 | 6153 | ||

| SJ4.0X4.5 | 4000 X4500 | 52.78 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 6397 | 7569 |

| SJ4.0X6 | 4000 X6000 | 71 | 33 | 1750 | Y160M-4 | 11 | GRF137-Y11-4P-44.65-M4 | 7681 | 9200 |

| SJ4.5X5.0 | 4500 X5000 | 74.75 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 8614 | 10864 |

| SJ5.0X5.6 | 5000X5600 | 104.5 | 31 | 2046 | Y160M-4 | 11 | XLD11-8-47 | 8740 | 14291 |

| SJ5.5X6.0 | 5500X6000 | 135.42 | 2100 | 12467 | 18745 | ||||

| SJ6.5X7.0 | 6500X7000 | 215 | 21 | 2400 | Y180L-4 | 22 | GRF147-Y22-4P-70.87 | 17890 | 25978 |

| SJ7.0X7.5 | 7000 X7500 | 269 | 2400 | Y200L2-6 | 22 | XLD22-10-47 | 20505 | 29030 | |

| SJ7.5X8.0 | 7500 X8000 | 331 | 23 | 2900 | Y200L2-6 | 22 | BLD7-43-22L | 22552 | 32796 |

| SJ8.0X8.5 | 8000X8500 | 402 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 30559.5 | 42467.3 |

| SJ8.5X9.0 | 8500X9000 | 480 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 34130 | 46623 |