Iron concentrate is the product of deep processing of iron ores. Natural iron ores need to go through crushing, grinding, magnetic separation (flotation/gravity separation) and other processes to select iron concentrate. In this process, iron concentrate dressing equipment, namely iron ore concentrator, will be used.

The iron concentrate powder is widely used. The ultra pure iron concentrate powder is mainly used in the production of metallized pellets, direct rolling of steel, magnetic materials, wastewater treatment, chemical pigments, batteries, high-purity sponge iron, smelting of special steel, production of liquid pig iron by smelting reduction, powder metallurgy and other fields.

What equipment must natural iron ore go through to become a useful iron concentrate powder? Let's get to know these iron ore dressing equipment.

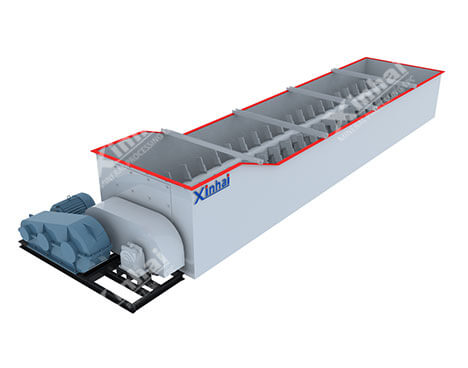

The mined natural ore contains a lot of mud. In order to avoid the useless work in the subsequent process and reduce the sliming degree of the pulp, the mined raw ore can be washed and pre selected first. The equipment required for ore washing includes spiral scrubber and high efficiency stirring scrubber, and the pre concentration is usually conducted by gravity concentration, usually using jigs and shakers.

There are many types of crushing equipment, including jaw crushers, hammer crushers, impact crushers, cone crushers, mobile crushers, roller crushers, etc. The principle of "more crushing and less grinding" should be followed when selecting crushing equipment to reduce energy consumption and improve economic benefits. In addition, the particle size and water content of iron ore shall be considered.

The grinding and classification equipment mainly includes ball mill and classifier. According to the demand of the number of grinding sections, the grid type ball mill shall be selected for the primary grinding, and the overflow type ball mill shall be selected for the secondary grinding or fine grinding. As for the selection of classification equipment, in addition to the traditional spiral classifier, hydrocyclones are also recommended for classification treatment. The advantages of hydrocyclones are small floor area, high classification efficiency and low price.

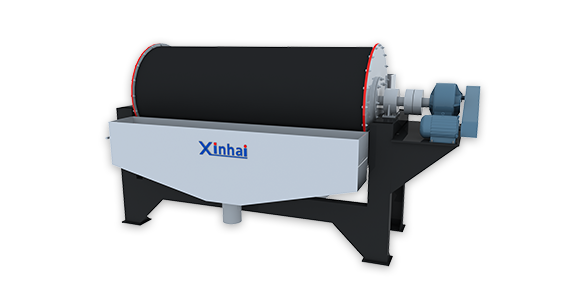

The magnetic separator is a process of flotation of iron concentrate powder. Its structural design is advanced, and its floor area is small, which can save many infrastructure costs. The magnetic separator produced by Xinhai has good magnetic separation effect, high production output, stable product operation, and can create more profits for users.

In addition to the above iron concentrate beneficiation equipment, for some ores that cannot be separated from iron concentrate by magnetic separation only, combined flotation or gravity separation process is required to achieve the goal. At this time, flotation machines, jigs, and shakers will be on the stage.

The above are the main beneficiation equipment needed for iron ore beneficiation. Other auxiliary equipment, including feeder, desliming equipment and dehydration equipment, are also indispensable. It can be seen that the process from iron ore to iron concentrate is a complex process and a complete industrial production line, which can not be solved by one or two kinds of equipment. Therefore, it is recommended that you consult with a regular manufacturer to design a suitable beneficiation scheme according to the ore properties and your requirements, so as to better complete the beneficiation recovery and select high-quality iron concentrate powder.