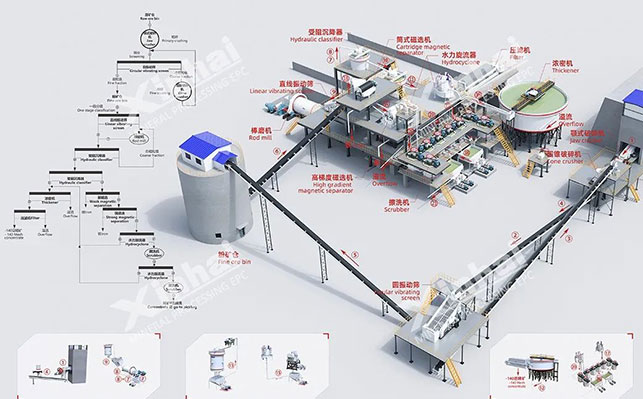

In 2021, Xinhai Mineral Equipment Co., Ltd. undertook a quartz sand purification project. After analyzing the beneficiation test of quartz ore sample and comparing several test results, it was finally decided to adopt the scheme of magnetic separation and purification of quartz sand, namely, crushing grinding magnetic separation dehydration process scheme. At the same time of meeting the mineral processing index, it ensures that customers can obtain a higher rate of return on investment.

Two half one closed circuit crushing and screening process is adopted in crushing and screening stage.

The specific process is: after mining, the raw ore is fed into the jaw crusher by the plate feeder for coarse crushing, and then sent to the round vibrating screen through 1 # belt conveyor for screening.

The materials on the screen are sent to No. 2 jaw crusher for intermediate crushing. The intermediate crushing products and the intermediate products of the vibrating screen are transported to the cone crusher by 2 # belt conveyor for fine crushing, and the fine crushing products and coarse crushing products are returned to the vibrating screen together to form closed circuit crushing.

The materials under the lower screen are the qualified materials in the crushing stage, which are transported to the powder ore bin by 3 # and 4 # belt conveyors.

One stage closed circuit grinding process is adopted in grinding and classification stage.

The specific process is as follows: a belt feeder is set at the bottom of the powder ore bin, which is fed into 5 # belt conveyor and transported to the overflow rod mill for grinding. A cylinder screen is set at the ore discharge end, and the material on the screen is transported by a large inclined belt conveyor and returned to the rod mill for regrinding. The pulp under the screen is pumped into the linear vibrating screen for screening, and the material on the screen returns to the rod mill for regrinding, forming a closed circuit grinding process.

Desliming+magnetic separation process is adopted in the magnetic separation stage.

The specific process is as follows: after the first stage grinding, the materials are screened by the linear vibrating screen. The pulp under the screen flows into the desliming bucket automatically for desliming. After desliming, the underflow flows into the medium field magnetic separator automatically for magnetic separation and impurity removal. After impurity removal, the pulp is quartz concentrate.

Grading+desliming process is adopted in dehydration stage.

The specific process is: the quartz sand concentrate after magnetic separation is pumped into the concentrated hydrocyclone for dehydration, and the underflow is the finished sand. The overflow of hydrocyclone and the overflow of desilter automatically flow into the sedimentation tank for clarification, and then they are returned as return water for reuse.

The project adopts a reasonable beneficiation process flow, which enables the project to obtain a higher beneficiation recovery rate and strive for a greater return on investment for customers. Different quartz sands have different properties, and the purification process needs to be determined through beneficiation tests.