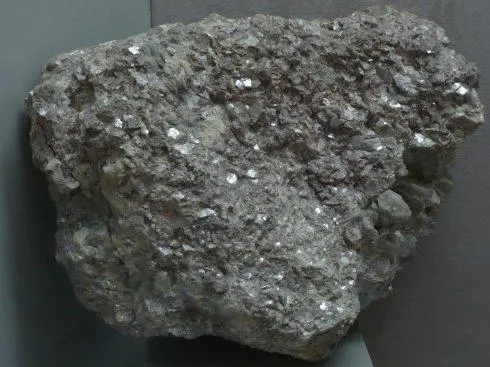

There are six main beneficiation methods for mica, including manual beneficiation, magnetic separation, flotation, friction beneficiation, air separation and mica shape beneficiation. The purpose of beneficiation of mica is to improve its grade and purity. The high-purity high-grade mica is widely used in coating, paint, electrical insulation and other industries. Next, we will introduce six mica beneficiation methods in turn.

The manual separation method is a method of manually separating mica. Some mica has been separated from each other in the mining process, or a hammer is used to remove the intergrowth and select mica in the manual beneficiation process.

The advantage of manual selection method is that it can be completed manually without purchasing complex equipment. However, in the 21st century, the labor cost may not be cheaper than buying equipment, so the manual beneficiation method has gradually been replaced by efficient and advanced mica beneficiation methods.

The gravity separation method is a mineral processing method that uses the different specific gravity of mica and gangue minerals, and uses their density difference or particle size difference to achieve separation. The commonly used gravity separation equipment includes shaking table, spiral chute, etc.

Although the gravity separation method has simple process and single equipment, the specific gravity of gangue mineral of mica and mica itself has little difference, so the gravity separation method of mica beneficiation is difficult to be widely applied.

The flotation method can be said to be a commonly used mica beneficiation method. The technological principle of flotation method is based on the difference of crystal structure and material composition between mica and gangue minerals, and realized by adjusting reagent conditions. Common equipment for flotation method includes agitation tank, flotation machine, etc. (Mica flotation production line)

The flotation method is mainly used to recover the fine mica with less than the outline area of mica crystal. The flotation method is often used for the beneficiation of crushed mica abroad. Two flotation methods have been successfully developed in the United States, one is to use cationic collectors to flotation mica in acidic medium, and the other is to use anionic and cationic collectors to flotation mica in alkaline medium. In addition, these two methods can also be used together.

Friction beneficiation is carried out according to the difference between the sliding friction coefficient of mica crystals and the rolling friction coefficient of round gangue blocks. There are many equipment used, including metal plate separator, spiral separator, inclined plate separator with deflector and inclined plate separator with "mound" plate.

When producing mica ore by this method, the production efficiency is relatively high, but there are also great shortcomings. The main reason is that when the ore thickness exceeds, mica crystals similar to gangue blocks are easy to enter the gangue, while flaky gangue may also enter the mica concentrate. Moreover, the current friction beneficiation process and mechanical equipment are not perfect, so friction beneficiation has not been widely used in the industrial production of mica beneficiation.

The air separation method is based on the difference in the settling speed of mica and gangue in the air flow. After the ore is broken, mica basically forms a thin sheet, while gangue minerals feldspar and quartz are massive particles. According to this, the selected materials are pre selected into narrow size fractions by multi-level classification. According to the difference of suspension speed in the air flow, special air separation equipment is used for separation. The process flow of "crushing classification air separation" is generally adopted.

The efficiency of this method is not high, and the final product needs to be obtained by multi-stage separation or in combination with other methods. According to the difference of settling velocity of ore particles in the air flow, the air separation method can be subdivided into chamber separation method, vibrating air separation method, air separation method and zigzag air separation method. Generally speaking, it is common to use air classifier for air separation in mica beneficiation.

Shape beneficiation method realizes separation according to different shapes of mica crystal and gangue, and the mechanical equipment used are cylinder screen and vibrating screen. This method generally uses more than two layers of sieves with different sieve openings. After the raw ore enters the screen surface, due to vibration or rolling, small pieces of flaky mica and gangue can leak from the first layer of screen cracks to the second layer of screen surface, and gangue will fall under the screen, while flaky mica will remain on the screen surface to achieve separation.

This method is widely used in mica mining enterprises due to its simple process, less equipment, high production efficiency and strong separation capacity.

The above is a detailed introduction to six mica beneficiation methods. In any case, it is recommended that you conduct beneficiation test on the ore first, and it is correct and wise to determine the beneficiation method according to the results of beneficiation test, which can ensure high income and high recovery.