A gold ore beneficiation line consists of at least 20-30 different types of equipment. It takes a lot of time and energy to select the machine models and purchase the complete set of equipment on your own. Therefore, it is advisable to choose a professional mining company to finish these complicated tasks for you, which not only saves worry and effort, but also saves money! Come to Xinhai, and you will have a complete set of gold mine beneficiation equipment in one stop!

What are the complete sets of equipment for gold beneficiation?

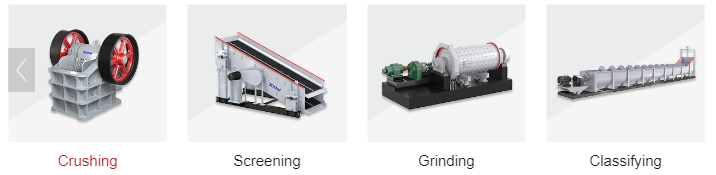

Before the gold ore enters the formal beneficiation process, it must be crushed and ground to a selectable particle size in order to better separate gold from other gangue minerals. This stage includes two processes of crushing-screening and grinding-classification. The equipment used includes crusher, vibrating screen, ball mill, classifier, etc.

The selection of beneficiation equipment should be determined according to the beneficiation test. Commonly used gold beneficiation methods include gravity separation method, cyanidation method, flotation method, etc., with different corresponding equipment.

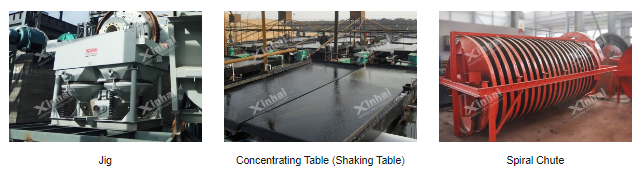

Gravity separation method is a simple gold separation method, with less investment and simple working principle. This method uses the different specific gravity of the material and the different sedimentation speed in the medium to separate gold, thus is suitable for single natural gold or gold ores with a large density difference between gold and gangue minerals Gravity separation is commonly used in placer gold mines.

Gold ore gravity separation equipment mainly comprises three types of equipment: jig, shaking table and spiral chute. Xinhai customized gravity separation process has a series of merits like more concise process, less pollution, lower energy consumption and lower cost. The total production efficiency can be increased by 35%, and the investment cost is reduced 20%.

Cyanidation process has strong adaptability to gold ore, especially to ores containing natural adsorbents such as clay, graphite, asphalt shale, iron oxide, and to complex gold ore such as arsenic gold ore.

The cyanidation process of gold ore is relatively complicated, but the recovery rate of gold is relatively high. The recovery rate of CIP and CIL can basically be stable at 80%, and can even reach more than 90%. Gold ore cyanidation equipment mainly includes: desorption electrolysis system, zinc powder replacement device, leaching agitation tank, washing thickener, carbon separator, air lifter, etc.

More than 80% of rock gold mines in China adopt flotation process to extract gold. Flotation cells are commonly used as gold ore flotation equipment. KYF/XCF flotation unit launched by Xinhai has successfully solved the step configuration problem of KYF flotation machine, which not only saves the consumption of foam pumps, but also reduces equipment management and maintenance operations. Besides, this flotation unit also greatly reduce investment costs when improving mineral processing efficiency, and therefore achieve the effect of 1+1>2.

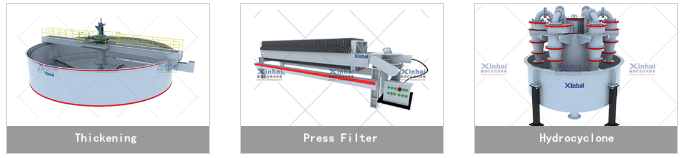

After the gold ore separation, the concentrate needs to be dehydrated. Different dewatering equipment is selected according to the project requirements, concentrate grade, pulp concentration, etc. The commonly used dewatering equipment are: thickener, hydrocyclone, filter, etc.

In addition to the above main equipment, transportation and slurry transportation equipment usually used as gold ore auxiliary equipment, with feeder, belt conveyor, wear-resistant slurry pump, mixing tank included.

There are more than 20 kinds of gold processing equipment introduced to you above. How to combine and connect these machines to form a complete gold ore beneficiation line? This requires professional mineral processing knowledge and a full understanding of the performance of each equipment! Xinhai has rich experience in gold beneficiation, and can provide you with services such as process design, equipment selection, and plant layout. Therefore, Xinhai can provide you a complete set of gold beneficiation equipment in one stop. If you want to invest in a gold processing plant, come and find us!