The common methods of gold tailings re-concentration include flotation, cyanidation and gravity separation, among which gravity separation is widely used in the application of gold tailings due to its advantages of large processing capacity, simple equipment structure, low operation cost and no pollution. However, according to the differences in the nature and treatment conditions of tailings, the role of gravity separation in the comprehensive recovery process of tailings is also different, which can be divided into three ways: pretreatment of tailings by auxiliary process, comprehensive recovery of tailings as a single process, and comprehensive recovery of tailings as a combination of main separation process and other processes.

In the process of comprehensive recovery of tailings, in view of the characteristics of associated components and particle size composition of some tailings, gravity separation can carry out rough separation or treatment of tailings in advance, providing conditions for further effective recovery of useful components. The process is as follows: screening and gravity separation of tailings and separation of light and heavy minerals.

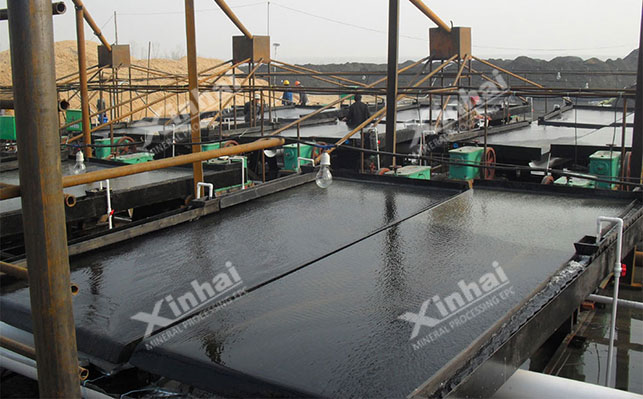

For some metal tailings with large mineral density differences and relatively single useful components, gravity separation can be used as a single process for comprehensive recovery of tailings, so as to realize the re-concentration of useful components.

In a gold mine tailings re-concentration process, part of the gold is wrapped in the heavy sand and lost into the tailings. Therefore, the gravity separation chute+shaking table is used to recover the heavy sand containing the wrapped gold in the tailings. The heavy sand is reground and re-concentrated, and the grade of the gold concentrate is more than 16g/t.

At present, in the process of tailings treatment in most metal mines in China, a single beneficiation process cannot achieve ideal results. In order to improve the comprehensive recovery and utilization of tailings, a combined beneficiation process consisting of multiple beneficiation processes is usually used. For example, in a gold tailings re-concentration and recovery operation, the combined process of magnetic separation-gravity separation is used to re-concentrate the tailings. First, the two-stage dry magnetic separation process is used to separate magnetite, hematite and the combination of ilmenite and garnet from the tailings, and then the gold in the tailings is separated by the shaking table.

The above two methods are commonly used in the recovery of gold mine tailings. Although the recovery of gold mine tailings is not easy, as long as a scientific and reasonable recovery scheme is determined through beneficiation test, its effect is also very good!