Flotation method is an important method for graphite beneficiation, and it is also more applied than other beneficiation methods. The principle of graphite ore flotation is to enrich the selected target minerals in the gas-liquid interface by adding a series of flotation reagents, so as to achieve the separation of impurity minerals and achieve the purpose of purification. This article will explain the graphite flotation process, flotation equipment and commonly used flotation reagents. Through an article, all aspects of graphite flotation are explained thoroughly.

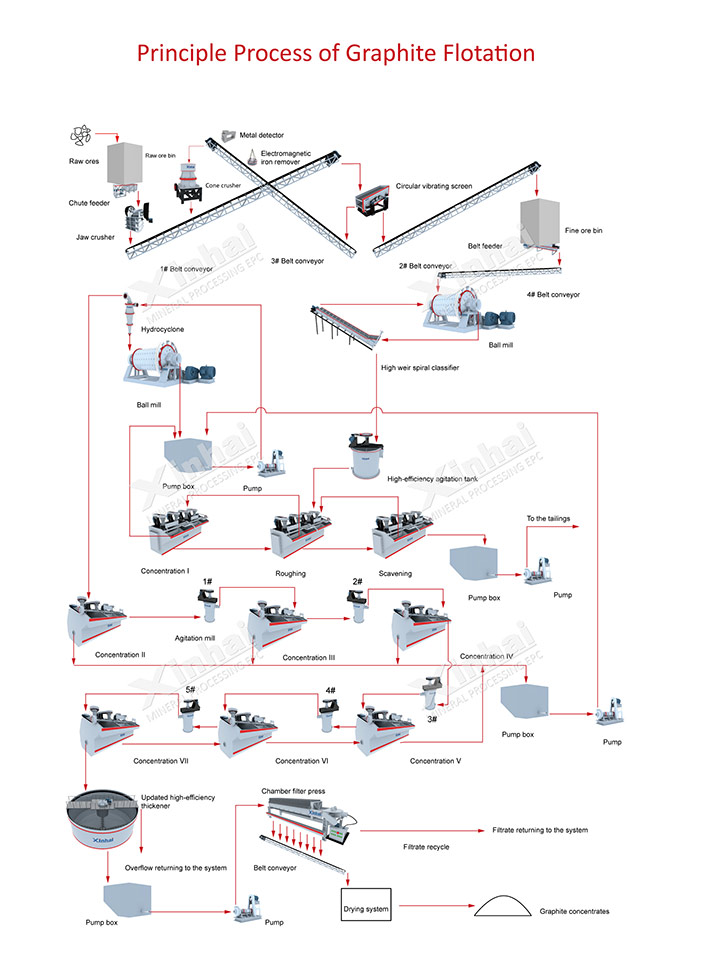

Graphite itself has good natural floatability and hydrophobicity, so conventional graphite ore can be purified by flotation process. In the purification process, in order to protect the large scale of graphite, the process flow of multi-stage grinding, multiple separation, and coarse concentrate regrinding and re-separation is generally adopted in the process. The following figure is the principle flow chart of graphite flotation process.

The flotation process of graphite ore mainly consists of ore preparation, slurry mixing and grinding and flotation process.

Fracture:

It mainly relies on crushing equipment to complete mechanical crushing through extrusion, impact, splitting and grinding, so as to realize the preliminary dissociation of graphite and gangue minerals. The hardness of graphite ore is generally medium hard or medium hard to soft, and the grade of raw ore is between 2% and 10%. The crushing process is relatively simple. The three-stage open circuit, two-stage open circuit or one-stage open circuit process is often used. If it is a small mine that processes weathered ore, it can be directly grinded without crushing.

Grinding:

This stage is to further realize the dissociation of graphite monomer or continuum after crushing. In order to select large scale graphite as early as possible, multi-stage grinding process is often used in the grinding stage to complete the separation with flotation. At this stage, ball mill, rod mill and stirring mill are commonly used as grinding equipment

classification:

Generally, it is combined with grinding to form a grinding and classification operation. After grinding, it is qualified to be mixed into the classifier equipment, and the solid particles are separated according to the size of particle size, so as to separate the qualified particle size products in time. Cyclone and spiral classifier are often used as classification equipment for graphite classification.

Slurry mixing is an important process in the process of mineral purification and separation, which can prepare for the subsequent separation operation. Generally, the agent is dispersed and fully contacted with graphite minerals by adjusting the slurry concentration.

The mixing operation of graphite ore concentrator can be divided into conventional mixing, aerated mixing and graded mixing, and then mechanical mixing, jet mixing and static mixing are used to complete the mixing.

According to the different types of graphite, the graphite flotation process is also different. The conventional flotation process is generally a closed circuit process of multi-stage floatation-middle ore sequential return or centralized return. When each stage of grinding operation is completed, it will enter the flotation stage. For example, after the first stage of grinding operation (the ore particle size reaches about 40% of - 200 mesh), a stage of flotation will be carried out, followed by multi-stage grinding and stripping, and multiple separation; The return of middling ore is the process that the middling ore produced after flotation is returned to the next level of operation in order or in concentration to improve the flotation efficiency of graphite ore.

Above, we have introduced the main process flow of graphite ore flotation, and the equipment used in each stage is as follows:

1. In the crushing stage, jaw crusher is often used for coarse crushing of large-grained minerals; Hammer crusher and impact crusher do medium crushing of minerals, cone crusher and roller crusher do fine crushing of minerals;

2. In the grinding stage, ball mill, rod mill, self-mill and other grinding equipment are used, and in the grading stage, spiral classifier or hydrocyclone are used for grading;

3. The slurry mixing stage is mainly completed in the mixing drum, slurry pre-processor, slurry preparation device and other equipment;

4. In the grinding and flotation stage, the overflow ball mill is often used for fine grinding, SF flotation machine and JJF flotation machine are used for rough and sweeping, and XJK flotation machine is used for cleaning.

In the actual beneficiation operation, in addition to selecting suitable flotation process, the selection of reagents is also particularly important. By adding reagents, the hydrophobicity of graphite can be improved, so as to improve the effective separation of graphite and gangue minerals. At present, the common flotation reagents for graphite ore are mainly collectors, foaming agents and regulators.

Graphite itself has certain floatability. It can also flotation graphite concentrate without the use of collectors, but the flotation efficiency is not ideal. Therefore, a thin oil film can be formed on the surface of graphite ore by adding collectors properly to enhance its hydrophobicity and make it firmly adhere to bubbles, thus improving the floatability of graphite and improving the recovery rate of concentrate. Common flotation reagents for graphite ore mainly include kerosene, diesel oil, liquid paraffin, heavy oil and other hydrocarbon oils.

The foaming agent is composed of polar and non-polar group molecules, in which the polar group is hydrophilic and the non-polar group is hydrophobic. By adding foaming agent, the mechanical strength of bubbles can be increased, and the number and size of bubbles can be controlled, the speed of bubbles rising can be controlled, and the distribution of bubbles can be changed. The common foaming agents for graphite ore include 2 # oil, 4 # oil, pine oil, cresol acid and camphor oil.

The purpose of the regulator is to adjust the effect of the collector and minerals, and to inhibit or strengthen the hydrophobicity of minerals. According to its different functions, it can be divided into three types: pH regulator, inhibitor and dispersant.

PH regulator: lime (CaO), NaCO3, Na (OH) 2 are commonly used;

Inhibitors: mainly water glass, sodium carboxymethyl cellulose, EDTA, tartaric acid, citric acid, oxalic acid, etc;

Dispersants: mainly include sodium silicate, sodium hexametaphosphate, sodium polyacrylate, etc.

Above, we introduced the process flow, equipment and common flotation reagents of graphite ore flotation. The graphite grade can reach 80%~90%, even about 95%, and the method has low drug consumption, low energy consumption and low cost. However, for graphite ore containing extremely fine silicate minerals and compounds of elements such as potassium, calcium, sodium, magnesium, aluminum, etc., monomer dissociation cannot be achieved at the grinding stage, and other processes need to be used for purification after flotation.