The gold heap leaching process is a method of extracting gold from gold tailings. After beneficiation, the gold tailings still contain many useful content, such as native gold, quartz, calcite, limonite, etc. At present, the gold tailings extraction methods mainly include conventional cyanide method, bromine method, thiosulfate method, and lime sulfur mixture method, which have achieved obvious results. So, how to use the heap leaching method to extract gold from tailings? Here is an introduction to the heap leaching process of gold mine tailings and its related application.

The heap leaching method for gold extraction has low requirements on terrain conditions, and can be adapted to local conditions. The storage yard can be set up according to the terrain characteristics. In addition, the heap leaching method also has the characteristics of simple process, convenient operation, less equipment, low investment cost and high efficiency.

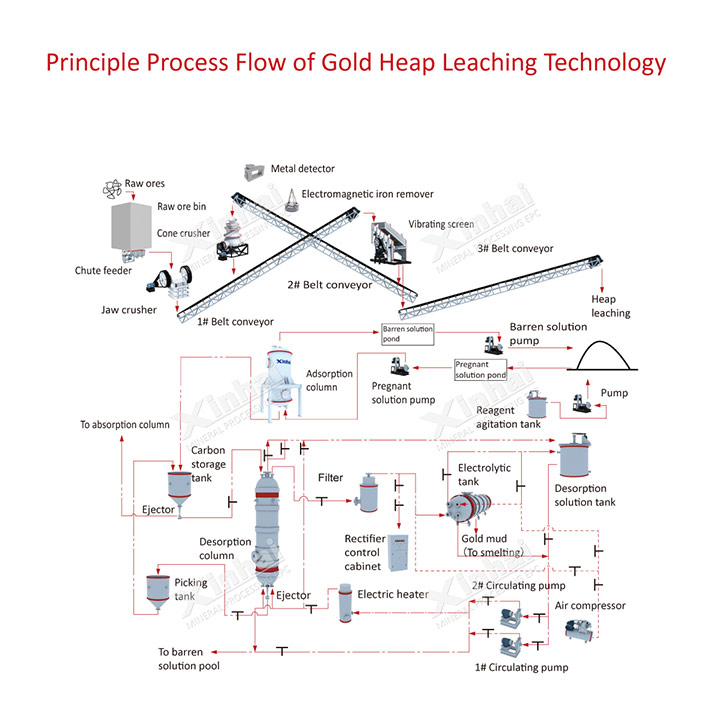

The gold tailings heap leaching process mainly has the following three steps:

1. Build a pile

The gold tailings are transported by forklifts to the ore stacking place for stacking.

2. Heap shower system

The pile shower system is set up on the laid mine pile After the cyanide solution reacts with the mine pile, the gold-containing solution (pregnant liquid) seeps out from the bottom of the mine pile and flows into the pregnant liquid pool, and then is pumped into the adsorption column by pump. The barren liquid will return to the shower system for reuse.

3. Pregnant liquid gold extraction

The high-efficiency and low-consumption fast desorption electrolysis system or zinc powder replacement device is used to extract the gold in the pregnant liquid, and to obtain the product after smelting.

Gold heap leaching method is often used to utilize gold deposits with small ore bodies or low grades, or both, or flotation tailings, which cannot be utilized by conventional methods. Gold heap leaching method is mainly used for the following mineral resources:

1. Large-scale, low-grade gold and silver mines that were previously considered unusable;

2. Low-grade gold-bearing "waste rock" stripped during mining;

3. Low-grade gold-bearing ores excavated in geological pit exploration and mine excavation;

4. Slightly higher gold-containing grade, but small scale mines that is not suitable to build a mechanized dressing plant;

5. Conventional cyanidation isn’t economically for gold extraction;

6. Gold-containing smelting slag, high-grade tailings and large-scale waste rock fields containing gold.

The above is the process flow of gold extraction from gold tailings by heap leaching. The heap leaching method has a limited scope of application, and the gold extraction method can be determined through beneficiation tests. Xinhai is good at gold extraction from raw gold ore and gold tailings. we has rich project experience and advanced technology. Welcome to contact us.