Tin has a soft texture, good ductility, and stable chemical properties. Tin and tin alloys are widely used in modern national defense, modern industry, cutting-edge science and technology, and human life. Tin ore beneficiation usually utilizes the difference between the density of tin ore and associated minerals, using gravity separation for beneficiation. What equipment does a tin ore dressing plant need?

In the crushing and screening stage, we need to crush the raw ore to 20mm, and then pass through a vibrating screen to divide the crushed ore into two particle sizes of 20-4 and 4-0mm.

The equipment used in the crushing and screening stage includes jaw crusher, hammer crusher, linear vibrating screen, and other equipment.

In the pre-selection stage, we need to enter 20-4mm ore into a heavy medium cyclone for pre-selection, and then use a jig for pre-selection after a section of rod grinding. The jig tailings are screened with a 2mm vibrating screen to remove+2mm as waste tailings, and - 2mm enters a shaking table for separation.

Therefore, the equipment used in this stage includes a heavy medium cyclone, rod mill, jig, shaking table, etc.

During the gravity concentration stage, the slime enters Φ 300mm cyclone, overflow and re flow Φ 125mm and Φ The 75mm hydrocyclone group removes fine mud, and the precipitated sand is concentrated and desulfurized by flotation, followed by cassiterite flotation.

Therefore, the equipment used includes hydrocyclones, jigs, shaking tables, etc.

Due to the fact that some tin ores often contain various iron oxide minerals (such as magnetite, hematite, limonite, etc.), tungsten ores, and other associated minerals, these minerals cannot be well separated from cassiterite through flotation and gravity separation. Therefore, magnetic separation is often used in ore washing processes to achieve tin iron separation. Tin ore magnetic separation is mainly conducted by wet high intensity magnetic separation, which is used for raw ore, secondary concentrate, and concentrate before entering the gravity separation operation. However, dry magnetic separation process is often used for separating tungsten and tin minerals.

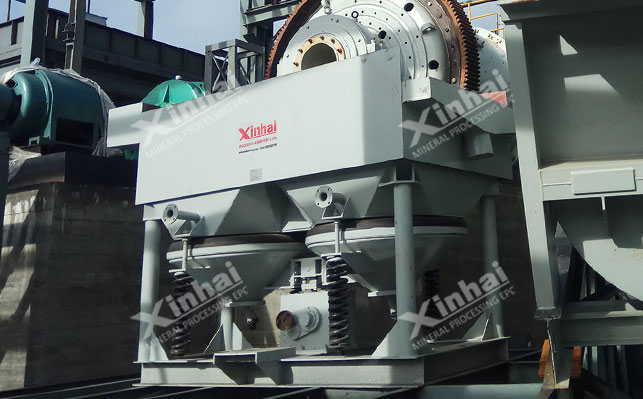

Common tin ore magnetic separation equipment includes wet magnetic separators and dry magnetic separators.

The above is all the equipment needed in the tin ore beneficiation process. Xinhai undertakes EPC services for mineral processing (EPCM). If you have any mineral processing needs, please contact us.