Potassium feldspar, also known as potassium feldspar ore, is an essential mineral resource widely used in ceramics, glass, metallurgy, and chemical industries. However, before extracting high-purity potassium feldspar powder from potassium feldspar ore, it usually needs to undergo a series of decomposition and purification processes. This article will provide a detailed explanation of the decomposition and purification process of potassium feldspar, highlighting the key steps and technological aspects involved.

Overview of the Process

The decomposition and purification process of potassium feldspar can be divided into several key steps:

Ore selection and ore pre-processing of potassium feldspar ore.

Alkaline leaching decomposition of potassium feldspar.

Separation and extraction of potassium feldspar from the alkaline leachate.

Fine processing and purification of potassium feldspar.

Step 1: Ore Selection and Ore Pre-processing

Before starting the decomposition and purification process, it is essential to select suitable potassium feldspar ore and perform ore pre-processing. The purpose of this step is to reduce impurity content and improve the ore's properties for subsequent processing. It typically includes the following operations:

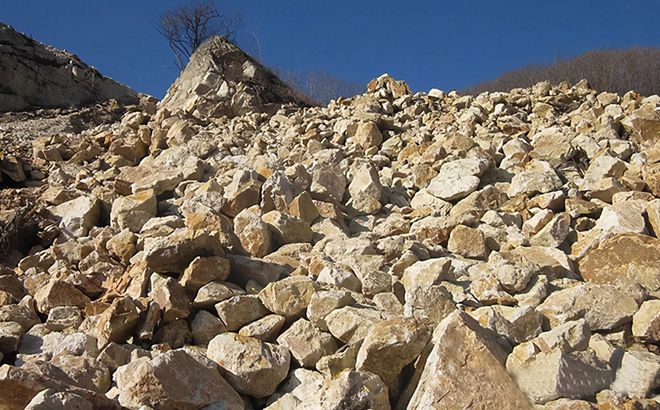

Ore Collection and Crushing: Firstly, potassium feldspar ore needs to be collected and crushed into suitable particle sizes for further processing.

Ore Washing: Washing is performed to remove surface impurities, such as dirt, to enhance the ore's purity.

Ore Drying: Drying operations help reduce the moisture content in the ore, reducing energy consumption in subsequent processing.

Step 2: Alkaline Leaching Decomposition of Potassium Feldspar

Alkaline leaching decomposition is one of the crucial steps in the decomposition and purification of potassium feldspar. In this process, an alkaline solution, typically sodium hydroxide (NaOH), is used to leach and extract potassium from potassium feldspar. The operating steps are as follows:

Alkaline Leaching Reactor: Potassium feldspar ore is usually introduced into a reactor where it reacts with the alkaline solution, typically under high temperature and pressure conditions to accelerate the reaction.

Potassium Dissolution: In the alkaline environment, sodium hydroxide reacts with the potassium in potassium feldspar, forming water-soluble potassium hydroxide (KOH). This reaction is critical as it effectively separates potassium from potassium feldspar.

Liquid-Solid Separation: The resulting slurry from the reaction needs to be separated from the unreacted ore solids. This is typically achieved through methods such as filtration or centrifugal sedimentation.

Step 3: Separation and Extraction of Potassium Feldspar

After successfully decomposing potassium feldspar, the next step is to separate and extract potassium ions from the alkaline leachate. This can be accomplished through crystallization and precipitation processes:

Potassium Crystallization: By controlling factors such as temperature, concentration, and pH, potassium hydroxide can be induced to crystallize from the alkaline leachate. These crystals can then be further refined to obtain high-purity potassium hydroxide.

Liquid-Solid Separation: The solution after crystallization needs to be separated from the remaining uncrystallized solution. This separation is usually carried out through methods like filtration or centrifugal sedimentation.

Step 4: Fine Processing and Purification of Potassium Feldspar

Finally, the separated and extracted potassium hydroxide can undergo a series of fine processing steps to obtain a high-quality potassium feldspar product. These steps may include:

Potassium Hydroxide Washing and Filtration: Washing can remove impurities from the potassium hydroxide, followed by filtration to separate the washed product.

Potassium Hydroxide Crystallization: Crystallization can be employed again to enhance the purity of potassium hydroxide by controlling crystallization conditions.

Potassium Hydroxide Drying: Drying is performed to transform wet potassium hydroxide into a powdered product.

The decomposition and purification process of potassium feldspar is a complex procedure involving multiple steps and technological considerations. By properly controlling operational parameters in each step, efficient and high-purity extraction of potassium feldspar can be achieved. This process is crucial for meeting the demands of industries such as ceramics, glass, metallurgy, and chemicals, while also promoting the sustainable development and utilization of potassium feldspar resources.