Before lithium ore enters the sorting stage, it needs to undergo a crushing and milling process to grind the raw ore to a qualified particle size. This is necessary before proceeding to the sorting stage, where lithium is separated from gangue minerals. The milling stage plays a crucial role in the entire ore processing flow, and the lithium ore milling process is outlined as follows:

Ore Collection: Lithium ore extracted is piled up for further processing, awaiting entry into the crushing process.

Ore Crushing: Lithium ore undergoes crushing through coarse and intermediate crushing equipment to facilitate subsequent milling. Jaw crushers are generally used for coarse crushing, while cone crushers are chosen for intermediate crushing.

Preparation of Milling Equipment

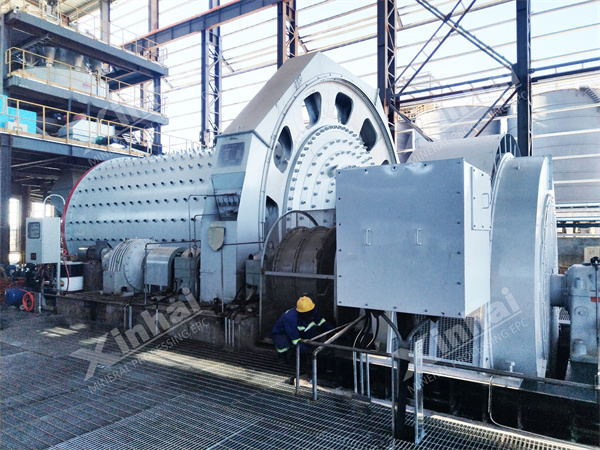

Milling Machine Selection: Based on beneficiation test data and plant scale, the milling equipment is determined, and the specifications and models of ball mills are consequently selected.

Ball Selection: Depending on requirements, suitable-sized and material-appropriate grinding balls are chosen, and they are proportionally configured according to different ball diameters (large, medium, small).

Milling Operation Steps

Feeding: Crushed lithium ore is loaded into the grinding cylinder of the milling machine.

Adding Water: A proper amount of water is added to the grinding cylinder at a certain ratio to form a suitable milling slurry.

Commencing Milling: The milling machine is started, and appropriate speed and time settings are configured to initiate the milling operation.

Adjustment of Milling Parameters

Adjustment of Milling Time: The milling time is adjusted appropriately based on the hardness and particle size characteristics of the ore to meet the requirements of particle size refinement.

Adjustment of Slurry Ratio: The water-to-powder ratio in the milling slurry is adjusted according to requirements and the characteristics of the milling machine to achieve effective milling.

Concentrate Separation

Coarse Concentrate Separation: The slurry after milling is screened using screening equipment to separate larger particles, forming coarse concentrate.

Flotation Separation: Flotation is employed to separate the concentrate by adding specific reagents that bind lithium ore particles to bubbles, causing them to float and be collected.

Concentrate Drying

Concentrate Drying: The concentrate is dried through drying equipment to reduce moisture content.

Concentrate Fine Grinding

Concentrate Fine Grinding: The concentrate undergoes further grinding using fine grinding equipment to achieve a finer particle size.

Through the lithium ore milling process, which includes crushing, milling, separation, drying, and fine grinding, lithium ore is ultimately transformed into lithium concentrate that meets experimental requirements. The application of this process provides technical support for the efficient utilization of lithium ore resources, contributing to the development of the lithium industry.