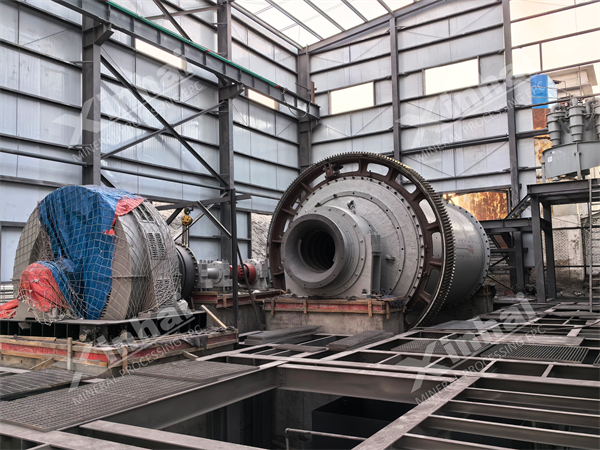

In the field of mining machinery, iron ore ball mills are one of the key equipment used for grinding iron ore and processing it into fine-grained materials suitable for subsequent processing. However, there are many types of ball mills in the market, and how to choose a suitable iron ore ball mill has become a concern for many mining enterprises. Next, we will introduce the production standards for iron ore ball mills, with a focus on the advantages of Xinhai's iron ore ball mills.

As an important equipment in mining machinery, the production standards of iron ore ball mills directly affect the performance, service life, and production efficiency of the equipment. In order to ensure the high quality and performance of iron ore ball mills, strict production standards must be followed. The following are some key standards and requirements that need to be followed in the production process of iron ore ball mills:

1. Design standards

(1) Structural design: The structural design of the ball mill must be scientific and reasonable, ensuring mechanical strength and stiffness to withstand high-strength working conditions. The design should include a reasonable lining structure, rotating components, and transmission system to ensure grinding efficiency and equipment stability.

(2) Material selection: Key components such as the cylinder, lining plate, and transmission device should be made of high-strength wear-resistant materials to ensure durability and long service life in high-strength grinding operations.

2. Manufacturing standards

(1) Machining accuracy: The machining accuracy of each component must meet the design requirements, especially the machining accuracy of the transmission components and bearing seats, which is crucial for the smooth operation of the equipment.

(2) Welding quality: High quality welding processes should be used at the welding site to ensure the strength and sealing of the weld, and to avoid equipment failures caused by poor welding.

(3) Assembly standard: The assembly of the ball mill should be strictly carried out in accordance with the assembly drawings and process requirements, to ensure the fitting accuracy and assembly quality of each component, especially the gear meshing and bearing installation.

3. Performance testing

(1) Operation test: After production is completed, no-load and load trial runs should be carried out to test the stability and noise level of the equipment, ensuring its reliability under different working conditions.

(2) Grinding efficiency test: evaluate the grinding efficiency and discharge particle size of the ball mill through grinding tests under actual production conditions, ensuring that the equipment can meet the designed production capacity and product quality standards.

4. Safety and environmental standards

(1) Safety design: The ball mill should be equipped with necessary safety devices, such as overload protection, emergency stop devices, etc., to ensure the safety of operators.

(2) Environmental requirements: The design and manufacturing of ball mills should comply with environmental requirements, minimize dust and noise pollution, and be equipped with effective dust removal and noise reduction devices to protect the health of operators and the working environment.

5. Intelligent standards

(1) Automation control: Modern ball mills should be equipped with advanced automation control systems that can monitor and adjust equipment operating parameters in real time, improve grinding efficiency and production stability.

(2) Fault diagnosis: Intelligent ball mills should have fault self diagnosis and alarm functions, which can timely detect and handle equipment faults, reduce downtime and maintenance costs.

The iron ore ball mills produced by Xinhai strictly follow these standards, which can significantly improve grinding efficiency, extend equipment service life, reduce production costs, and bring greater economic benefits to mining enterprises. In addition, the ball mill of Xinhai Iron Mine also has the advantages of energy conservation, large output, and high efficiency.

As a leading enterprise in the mining machinery industry, Xinhai Mining Machinery enjoys a high reputation in the market for its iron ore ball mills. The following are several advantages of Xinhai Iron Mine ball mill:

1. Energy saving: The Xinhai Iron Mine ball mill adopts advanced energy-saving technology, significantly reducing energy consumption. Its efficient energy-saving motor and optimized grinding chamber ensure lower power consumption under the same conditions.

2. Large output: The structural design of Xinhai ball mill is scientific and reasonable, with a large amount of material passing through and a significant increase in processing capacity per unit time. Especially suitable for the needs of large-scale mining enterprises.

3. High efficiency: The Xinhai ball mill can fully utilize the impact and grinding effects of steel balls during the grinding process, improving the grinding efficiency. Its special lining design can effectively improve the movement trajectory of the grinding medium, making the grinding effect more significant.

4. Uniform discharge: The Xinhai ball mill is equipped with an efficient classification device at the discharge end to ensure uniform and consistent discharge particle size, meeting the needs of different ore processing.

5. Intelligence: Xinhai's iron ore ball mills are equipped with advanced automation control systems, which can monitor the grinding situation in real time and adjust operating parameters. Intelligent control not only improves the convenience of operation, but also significantly reduces labor costs and operational risks.

In summary, selecting a good iron ore ball mill requires comprehensive consideration of multiple factors, and Xinhai Mining Machinery has become a highly favored brand in the market due to its significant advantages in energy conservation, high production, efficiency, uniform discharge, and intelligence. For mining enterprises, choosing Xinhai's iron ore ball mill is undoubtedly a wise choice to improve production efficiency and reduce costs.