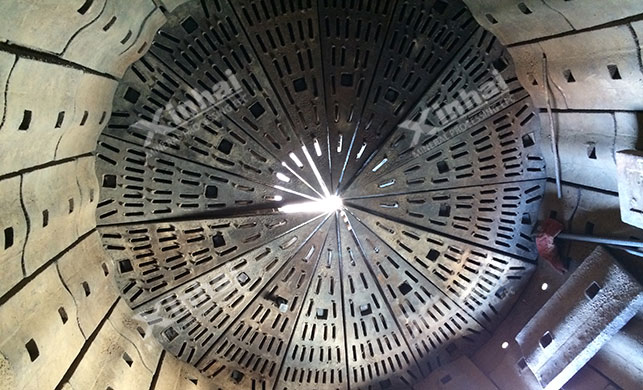

Ball mill is a commonly used grinding equipment in mineral processing plants, and it is also the core equipment. In the production process, if we encounter the problem of the lining plate of the ball mill falling off, how should we solve it? This article provides an introduction to the causes, treatment steps, and preventive measures of lining plate detachment.

The detachment of the ball mill liner may be caused by various reasons, including:

1. Design issues

The design of the lining plate is unreasonable, such as insufficient thickness or improper material selection, which may result in the lining plate being unable to withstand the stress and impact under normal working conditions, leading to detachment.

2. Improper operation

Improper operation of the ball mill during operation, such as excessive feeding speed, overload operation, frequent starting and stopping, can exert excessive force and impact on the lining plate, accelerating its wear and detachment.

3. Grinding medium issues

Inconsistent size and hardness of grinding media, or the use of excessive impact force, can also lead to lining plate wear and detachment.

4. Material and heat treatment process issues of lining plates

The unreasonable material and heat treatment process of the lining plate may reduce its fatigue strength and service life, leading to plastic deformation or fracture of the lining plate under stress.

5. Operation status issues of ball mill

Abnormal operation status of the ball mill, such as direct impact of steel balls on the lining plate during low load operation, can also cause severe wear and even fracture of the lining plate.

When the lining plate of the ball mill falls off, the following steps should be followed for treatment:

1. Shutdown handling: Firstly, the operation of the ball mill should be immediately stopped to prevent the liner from falling off and causing greater damage or safety accidents.

2. Dismantling the lining plate: While ensuring safety, remove the detached lining plate and clean the working surface of the lining plate until a bright metal part is exposed.

3. Preparation for welding: Insert graphite plugs into the bolt holes of the lining plate to ensure that the bolt holes do not become smaller after welding, making it easier to fix the lining plate.

4. Welding operation: Place the lining plate to be repaired on the welding workbench with the work facing upwards. Use low hydrogen welding rods, such as tdmn (180) or tdcrmn (220), for overlay welding. The overlay welding is divided into multiple layers, including steel overlay welding layer, composite overlay welding layer, and wear-resistant alloy overlay welding layer. Each layer of welding should be smooth and flat to reduce the amount of repair.

5. Trimming the working surface: After completing the overlay welding, clean the welding slag and other debris, and remove burrs around the lining plate.

6. Reinstallation: After ensuring that the liner has been completely repaired and cooled, reinstall the liner and tighten the bolts.

7. Inspection and trial operation: After installation, check to ensure that the lining plate is securely installed without looseness or other problems. Then conduct a trial run and observe whether the operation status of the ball mill is normal.

Instead of waiting for problems to arise before thinking about solutions and solutions, it is better to prevent them in advance and try to avoid liner detachment as much as possible. To prevent liner detachment in ball mills, the following measures can be taken:

1. Regular inspection: Regularly inspect the lining plate of the ball mill to promptly detect signs of wear and damage.

2. Reasonable design: Ensure that the design of the lining plate is reasonable, including thickness, material selection, etc., to adapt to the working conditions of the ball mill.

3. Correct operation: Ensure that operators follow the operating procedures to avoid damage to the lining plate due to improper operation.

4. Maintenance: Regular maintenance and upkeep of the ball mill, including lubrication, tightening, etc., to extend the service life of the lining plate.

In summary, when selecting a ball mill, we should fully consider whether the design of the lining plate is reasonable and whether the material is suitable. Before equipment operation, a trial run should be conducted, and during operation, standardized operations should be carried out. Necessary preventive measures should be taken to prevent the lining plate from falling off. Once the lining plate falls off, the above processing steps can be followed for handling. After the problem is solved, production should be resumed as soon as possible to avoid project delays.