In the complex processes of the steel industry, iron powder is a fundamental and critical raw material widely used in various fields such as metallurgy, chemical industry, and building materials. However, iron powder often contains impurities such as sulfur, which poses a potential threat to product quality. This article will explore the key methods for removing sulfur from iron powder, in order to improve the overall quality of the product.

Firstly, how is sulfur generated in iron powder? During the reduction and grinding process of iron ore, sulfur elements often exist in the form of compounds in iron powder. When iron ore is reduced to iron powder at high temperatures, these sulfur compounds do not completely disappear, but become a hidden danger that affects the purity of iron powder. The presence of sulfur can increase the brittleness of steel materials, seriously affecting their mechanical properties, especially in cold environments, where this problem is more prominent. Therefore, removing sulfur from iron powder is a key step in improving the quality of steel.

So, how to effectively remove sulfur from iron powder? The following are several commonly used methods:

1. Physical beneficiation methods: By magnetic separation, gravity separation, or flotation, low sulfur iron ore can be pre selected to reduce the source of sulfur in iron powder. This method is suitable for situations where the sulfur content in iron ore is low.

2. Chemical beneficiation method: Specific chemical reagents such as sodium sulfate and sodium carbonate are used to react with sulfides to form soluble salts, which are then removed by water washing. This method can thoroughly remove sulfur from iron powder.

3. Thermodynamic method: At high temperatures, sulfides are converted into sulfur dioxide gas through oxidation-reduction reactions, thereby separating them from iron powder. This requires higher temperature and specific atmosphere control.

4. Biological beneficiation method: Utilizing the action of certain microorganisms to decompose sulfides and convert them into sulfates or other forms of sulfur compounds, facilitating subsequent separation and removal.

For different types of iron powder and sulfur content, the above methods can be used individually or in combination. For example, for iron powder with low sulfur content, physical and chemical beneficiation methods are very suitable; For high sulfur iron powder, thermodynamic or biological beneficiation methods need to be used. In addition, the sulfur content in iron powder can be fundamentally reduced by improving production processes, such as optimizing reduction conditions and selecting low sulfur raw materials.

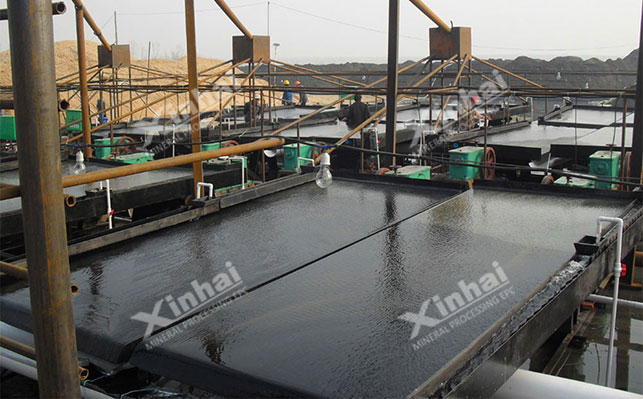

The beneficiation equipment and technical services provided by Xinhai Mining Equipment can effectively assist in the sulfur removal process. Our equipment covers multiple stages such as crushing, grinding, classification, flotation, etc., and can meet the needs of different types of iron powder processing. At the same time, our expert team will provide customized process plans based on the actual needs of customers to ensure the best sulfur removal effect. Xinhai Mining Equipment is committed to providing comprehensive solutions, from equipment selection to process design, to later operation and maintenance, providing full support to help you easily cope with sulfur removal challenges.

Overall, sulfur removal from iron powder is a systematic project that requires comprehensive consideration of raw material characteristics, process flow, and cost-effectiveness. Through scientific and reasonable methods and the application of high-quality equipment, we are fully capable of controlling sulfur content within the ideal range, improving the quality of iron powder, and promoting the green development of the steel industry.