Gold copper ore refers to ores containing two metal elements, gold and copper, and is an important multi metal coexisting mineral resource. In this type of ore, gold and copper often exist in different mineral forms, such as natural gold, chalcopyrite (copper sulfide), malachite, etc. The beneficiation method of gold copper ore usually involves extracting these two valuable metals from the ore.

The beneficiation process of gold copper ore is relatively complex, as the physical and chemical properties of gold copper are different, requiring different beneficiation techniques and processes to effectively separate and extract. The common beneficiation methods include the following four types:

The gravity method is a method of separation based on the density difference between gold copper ore. Firstly, the gold copper ore is subjected to crushing and grinding treatment, and then heavy metal gold particles are separated from light metal copper minerals using gravity separation equipment. Gold particles are usually located at the bottom or bottom of gravity beneficiation equipment, while copper minerals are located at the top or upper layer. The separated gold copper ore are called concentrates, while the unseparated portion is called tailings. Concentrates are typically subjected to further processing to improve the grade of gold and copper, while tailings may be processed or stored to reduce environmental impact.

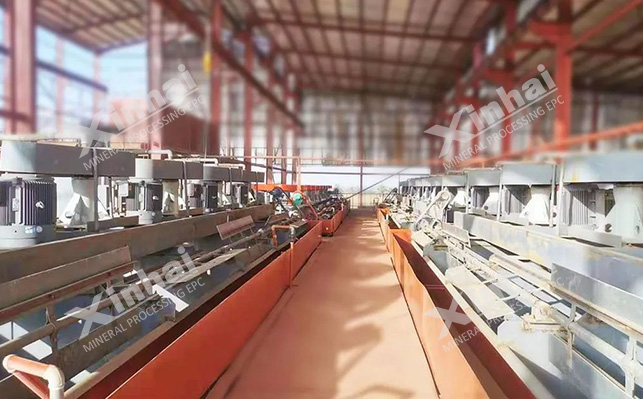

Flotation method is a method of separation that relies on the differences in mineral surface properties. Firstly, after crushing and grinding the gold copper ore, various chemical agents are added to the slurry to change the surface properties of the mineral. Then, air or other gases are injected into the flotation cell to generate bubbles. These bubbles attach to gold or copper mineral particles and float them to the surface of the flotation cell. As the flotation process progresses, gold copper ore form floats or concentrated products that can be collected and further processed.

(1) Grinding and floating method

The re grinding and re flotation method is to finely grind the flotation tailings and then perform flotation to recover copper and gold minerals from the tailings, thereby improving resource recovery rate.

(2) Mixed flotation method

The mixed flotation method is to mix the re selected flotation concentrate with the original flotation concentrate for unified concentrate treatment.

The selection and application of the above various beneficiation methods should be based on factors such as the specific properties of the ore, economic considerations, environmental requirements, etc., to ensure the efficiency and economic rationality of the beneficiation process.

Magnetic separation is a physical separation method used to remove iron minerals and other iron impurities from ores containing gold and copper. This process depends on the magnetic differences between different minerals, as iron minerals typically have magnetism, while gold copper ore typically do not. Firstly, the gold copper ore is broken into appropriate particle sizes and refined through the grinding process, which helps to release gold copper ore as well as iron minerals. Afterwards, the ore is fed into equipment such as a magnetic separator or magnetic drum, which generates a magnetic field to attract magnetic iron minerals, while gold copper ore are not attracted.

Heap leaching is a commonly used method for extracting gold from low-grade gold copper ores. The ore is crushed and stacked in piles, then immersed in a solution to dissolve the gold. The generated gold containing solution is collected and processed to recover gold. Firstly, the gold copper ore is crushed into appropriate particle sizes and stacked in a special open-air stacking area. Subsequently, the accumulated ore will be regularly or continuously sprayed with a solution containing specific chemical agents. For gold minerals, the commonly used leaching solution is a solution containing cyanide, while for copper minerals, leaching solutions containing sulfuric acid may be used. The leaching solution penetrates into the ore pile and reacts with the gold copper ore inside, causing the gold copper to dissolve from the ore into the leaching solution.

The gold copper ore beneficiation technology has made certain progress in

recent years, but there are still some technical challenges and shortcomings,

such as mineral complexity, limitations of flotation processes, environmental

issues, and the research and application of new technologies.