When it comes to the flotation of lead-zinc ores, selecting the right equipment is crucial for achieving both operational efficiency and environmental stewardship. A typical setup for an 800-ton-per-day flotation plant should include several key pieces of equipment, each playing a vital role in the overall process.

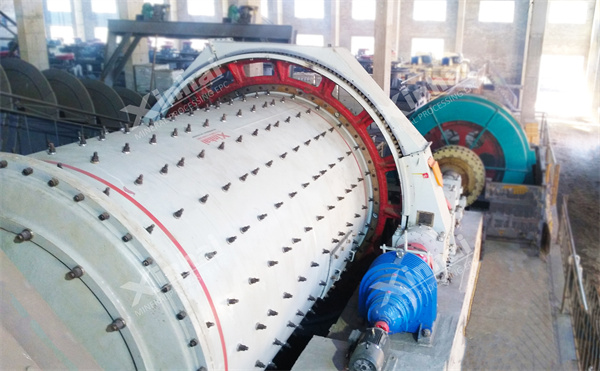

The initial step involves crushing and grinding the ore to liberate the mineral particles. High-capacity crushers, such as gyratory or jaw crushers, are used to reduce the ore size, followed by ball mills or cone crushers to further grind the ore to the required fineness. This ensures adequate exposure of mineral surfaces for subsequent flotation.

After crushing and grinding, classifying equipment like hydrocyclones or vibrating screens separate the ore into different particle sizes, preparing it for the flotation stage. This step enhances the efficiency of the flotation process by ensuring a uniform feed size.

The heart of any flotation process is the flotation cell, where the valuable minerals are separated from waste materials. For an 800-ton-per-day operation, large-scale flotation cells or banks of cells are necessary. These cells should be energy-efficient and designed for high-throughput while maintaining precise control over air dispersion and mixing intensity.

Pumps transport the slurry to the flotation cells, and feeders ensure a consistent supply of ore to the grinding circuit. High-volume pumps and accurate feeders are essential for uninterrupted operation and precise control over the flotation process.

Addition of flotation reagents, such as collectors, frothers, and pH regulators, is managed through automated systems that dose the chemicals accurately. This is critical for enhancing mineral recovery and selectivity, making it a significant aspect of the flotation technology.

Once the flotation is complete, dewatering equipment like thickener tanks and filter presses are used to remove excess water from the concentrate, preparing it for further processing or storage. Efficient dewatering reduces transportation costs and environmental impacts.

Modern flotation plants rely on sophisticated automation systems to monitor and adjust process variables in real-time. PLC-based control systems with advanced sensors ensure optimal operation, reducing human error and increasing recovery rates.

Given the stringent environmental regulations, equipment that minimizes emissions and chemical usage is paramount. Advanced scrubbers and emission control systems help in maintaining clean air outputs, aligning with sustainable mining practices.

Effective tailings management is crucial for environmental protection. Equipment that handles and disposes of tailings responsibly, without causing harm to the environment, is a must. This includes modern tailings disposal systems that minimize land use and potential pollution.

This includes conveyors, feed hoppers, and other supporting machinery that facilitate the smooth flow of materials throughout the process. Reliable and durable auxiliary equipment is necessary for continuous operations.

For an 800-ton-per-day lead-zinc flotation plant, the choice of equipment should prioritize energy efficiency, minimal maintenance, and ease of operation. It's also important to consider the supplier's reputation, technical support, and the equipment's track record in similar applications.

Investing in the right flotation equipment is essential for the economic and environmental success of your lead-zinc mine. By choosing equipment that meets these criteria, you can ensure a profitable and sustainable operation. Remember to consult with industry experts who can provide tailored solutions based on your specific ore characteristics and site conditions.

Call to Action: Contact us for a customized solution that fits your lead-zinc flotation needs and discover how our advanced equipment can optimize your 800-ton-per-day processing capacity.