In the mining and chemical industries, thickener is a key solid-liquid separation equipment that provides convenience for subsequent process flow by increasing the concentration of slurry or pulp. With the development of technology, various types of thickeners have emerged in the market, among which tilted plate thickener and high-efficiency thickeners are highly favored due to their unique design and performance. This article will explore the differences between these two thickeners from a professional perspective and analyze their applicability in industrial applications.

The design concept of the tilted plate thickener is to increase the settling area and improve settling efficiency by adding inclined plates to the thickener. This design enables the tilted plate thickener to perform well in handling low concentration, high flow materials. The addition of inclined plates not only increases the settling area, but also promotes the settling of solid particles by changing the fluid dynamics conditions. In addition, the structure of the tilted plate thickener is relatively simple, easy to install and maintain, and the operating cost is also relatively low.

Compared with the tilted plate thickener, the efficiency thickener adopts a more advanced design concept. These devices are typically equipped with optimized mixing systems and more rational settling zone designs to achieve higher thickening efficiency. The automation level of high-efficiency thickeners is relatively high, and many models are equipped with automation control systems that can automatically adjust operating parameters based on material characteristics, improving operational flexibility and stability. In addition, the high-efficiency thickener has a large processing capacity and is suitable for large-scale production needs.

In practical applications, both tilted plate thickener thickeners and high-efficiency thickeners have their own advantages. The tilted plate thickener is favored by some small and medium-sized mining or chemical enterprises due to its simple structure and low cost. However, high-efficiency thickeners have advantages in large-scale industrial production due to their high efficiency, high degree of automation, and large processing capacity. Here is a comparison of these two thickeners in several key aspects:

Settling efficiency: High efficiency thickeners usually have higher settling efficiency, especially when dealing with materials that are difficult to settle, their advantages are more obvious.

Energy consumption and operating costs: Although the initial investment of an efficient thickener may be high, its energy-saving design and high efficiency can reduce long-term operating costs.

Applicability: The tilted plate thickener is suitable for application scenarios that do not require particularly high settling efficiency, while the high-efficiency thickener is more suitable for industrial environments that require high efficiency and automation.

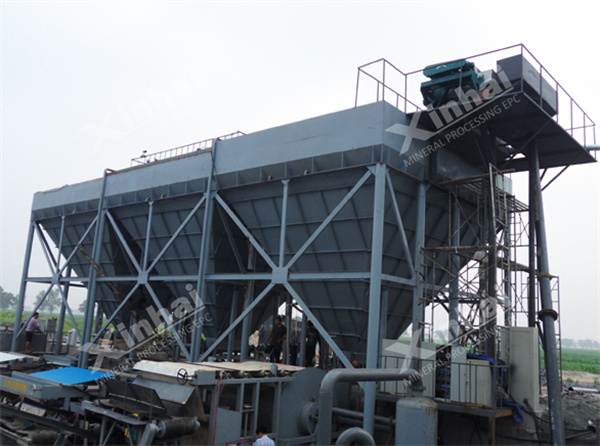

As a professional mining equipment manufacturer, Xinhai Mining Equipment understands that different customers have different needs. Therefore, we offer a variety of solutions including tilted plate thickener and high-efficiency thickeners. Our equipment meets the needs of enterprises of different sizes with its high efficiency, stability, and ease of maintenance. Whether it is a cost-effective tilted plate thickener or an efficient thickener that requires high efficiency and automation, Xinhai Mining Equipment can provide customized solutions.

The tilted plate thickener and high-efficiency thickener each have their own

characteristics and applicable scenarios. The selection of which type of

thickener to use depends on specific application requirements, material

characteristics, and production scale. Xinhai Mining Equipment, with its

professional knowledge and technical accumulation in the field of mining

equipment, can provide customers with thickener equipment that is more suitable

for their production needs. We believe that through Xinhai Mining's professional

services, customers can achieve greater production efficiency and lower

operating costs.