Gravity beneficiation of gold mines, as an ancient yet highly effective mineral processing technique, is mainly based on the density difference between gold and other minerals, and is a mineral processing method that separates impurities such as gold and gangue in a gravity field or centrifugal field. The density of gold is relatively high, usually around 19.3g/cm ³, while the density of most gangue minerals is relatively much lower. This significant difference lays the physical foundation for gravity based gold selection. In general, if the density of gold ore particles is higher than that of heavy media, they will sink, while vein minerals with a density lower than that of heavy media will float up, in order to achieve separation.

Gravity beneficiation of gold mines has a long history of application in sand gold beneficiation, and is often used as an important pretreatment or selection step in the beneficiation process of rock gold ore.

The methods of Gravity beneficiation of gold mines can be selected according to the different particle sizes of the gold ore, mainly including jig selection, shaking table selection, spiral chute selection, and heavy medium selection.

Jigging beneficiation is based on the differential motion of mineral particles in vertical alternating water flow for separation. In the jig, the water flow will periodically rise and fall. When the water flow rises, the bed is lifted and mineral particles begin to loosen; When the water flow decreases, gold particles with higher density can quickly move downwards through the gaps in the bed, while vein minerals with lower density remain in the upper layer. Under the combined influence of gravity, water flow impact, and particle interactions, gold particles gradually concentrate at the bottom of the bed during multiple cycles, thereby achieving separation.

Jigging has good adaptability to different particle sizes of gold ores, and can effectively separate both coarse-grained and fine-grained ores, obtaining gold concentrates with a certain grade. However, the effectiveness of gold selection by jigs will be affected by the particle size composition of the ore and the operating parameters of the jigs (such as stroke, punch, etc.). It is suitable for beneficiation plants of various scales, and can be used as a roughing equipment to process large amounts of raw ore, as well as playing a role in the beneficiation process.

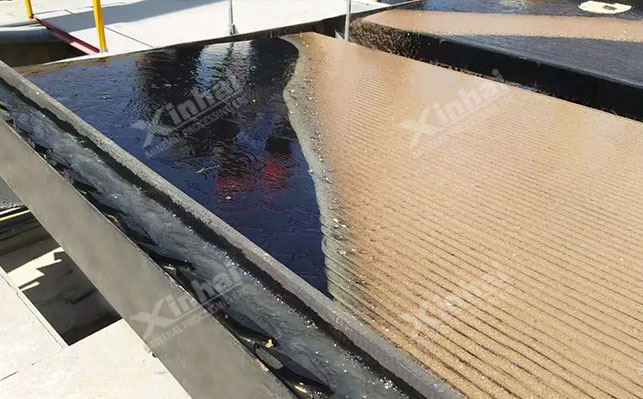

Shaking table beneficiation is the process of separating ore particles by utilizing the differences in their movement on an inclined bed surface. The table surface of a shaker is usually covered with grooves or rough paving materials. When the shaking table is shaken, the slurry forms a fan-shaped flow on the bed surface. At the same time, due to the lateral water flow generated by the inclination and shaking of the bed surface, the gold particles move laterally along the bed surface under the combined effects of gravity, friction, and water flow impact, and accumulate in different areas of the bed surface according to their density and particle size.

The shaking table has a good separation effect on fine and micro fine gold ores, and can obtain high-grade concentrates. However, the processing capacity of the shaker is relatively small, making it suitable for selection operations or small-scale beneficiation plants that process low-grade ores.

Chute beneficiation is the process of separating ore particles by utilizing their motion characteristics within a chute with a certain slope. The groove body of a chute is usually a flat surface with a certain roughness or a bottom surface with specific patterns. When the slurry enters the chute, it flows downwards along the chute under the action of gravity. At the same time, due to the slope of the chute and the fluidity of the slurry itself, a certain amount of water flow force is generated. Gold particles gradually settle and move in the chute under the combined effects of gravity, friction between the tank and other particles, and the impact of water flow. Based on the difference in density compared to other minerals, gold particles tend to aggregate in specific areas at the bottom of the chute, while vein minerals with lower density are carried away by the water flow.

The selection of gold through chutes has a significant effect on the separation of medium and fine-grained gold ores, and can obtain relatively high-grade gold concentrates. However, the recovery rate of chute gold selection may be affected by factors such as slurry flow rate and ore feed rate. It is suitable for processing ores with less coarse gold content and is widely used in some small-scale beneficiation plants or as a link in joint beneficiation processes.

Heavy medium beneficiation is the process of separating gold and other minerals by utilizing their different flotation and sedimentation characteristics in a medium with a density greater than water. Heavy media is usually a suspension formed by mixing finely ground high-density solid particles with water, and its density can be adjusted as needed. When gold ore particles enter the heavy medium, under the combined effect of gravity and medium buoyancy, gold particles with a density greater than the heavy medium will sink, while vein minerals with a density less than the heavy medium will rise. In this process, due to the uniform distribution of heavy medium in the beneficiation equipment, gold particles overcome the resistance of the medium with their higher density and settle towards the bottom of the equipment, while those minerals with lower density are pushed in different directions by the buoyancy of the medium.

Heavy medium gold selection has an ideal separation effect on ores with

relatively large particle sizes, which can efficiently separate gold from a

large amount of vein minerals and obtain high-purity gold rich materials.

However, this method requires precise control of the density of the heavy

medium, and the process of medium recovery and purification is relatively

complex. It is suitable for processing ores with moderate particle size and

significant density differences between gold and gangue minerals, and can play

an efficient separation advantage in large-scale beneficiation operations,

improving the overall efficiency of beneficiation.