The core principle of placer gold ore beneficiation is to recover gold and its associated heavy minerals from the original ore to the maximum extent through gravity separation, and then separate gold from heavy minerals through combined processes such as gravity separation, flotation, mercury mixing, magnetic separation and electrostatic separation to achieve comprehensive recovery. The placer gold ore beneficiation process generally includes three main links: crushing and screening, desludging and separation.

1. Crushing and screening

Placerous gold ore often contains cemented mud lumps. If these mud lumps are not crushed, they will be discharged with waste rock during the screening process, resulting in gold loss. At the same time, the cement mud may also adhere to gravel or pebbles, which will also cause gold loss if not crushed. Screening operations can remove 20-40% of waste rock and are an indispensable part of placer gold beneficiation.

On gold mining ships, crushing and screening operations are usually completed simultaneously inside the drum screen. The drum screen is equipped with intermittent spiral angle steel, and a certain water pressure must be maintained during operation. In fixed land concentrators, a washing bed must be set up for crushing and screening, and a specific type of water gun is usually used for flushing.

Flushing on the screen can not only improve the screening efficiency, but also further crush the cement mud. Therefore, the screening operation of placer gold mines mostly adopts water screening. The amount of water flushing on the water screen needs to be determined according to the requirements of ore washing, and try to meet the concentration requirements of the next stage of sorting operations.

2. Dehydration

In the gold placer, materials smaller than 0.1 mm usually have very low gold content or no gold. Therefore, in the placer gold mechanical concentrator, efforts are usually made to remove this part of the ore mud to reduce interference with the separation process.

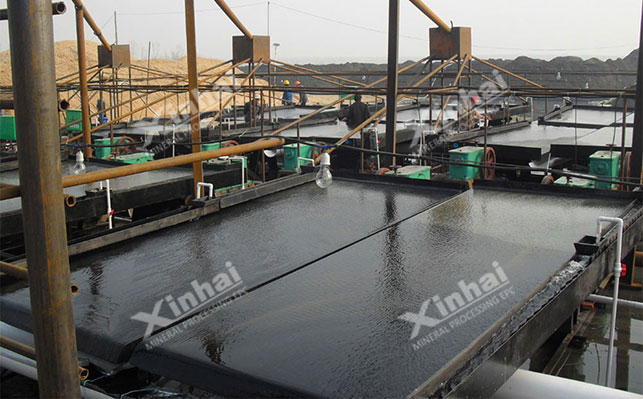

3. Separation

Practice has proved that gravity separation is an effective and economical method for treating gold placer. Due to the different particle size composition of gold in the placer gold ore, the effective particle size limit of various gravity separation equipment for processing materials is also different. Therefore, the reasonable placer gold ore separation process should be the joint operation of several gravity separation equipment.

For the treatment of gold-containing coarse concentrate, there are currently three main methods: (1) manually washing out gold particles with a gold pan and discarding the heavy sand; (2) using an amalgamation cylinder for internal mercury mixing, obtaining mercury paste and discarding the heavy sand; (3) after manual panning or mercury mixing to extract gold, the heavy sand is sent to the concentrate plant for processing, and various heavy sand minerals are recovered separately by magnetic separation, electric separation and other methods.

In the crushing and screening stage, commonly used equipment includes grid screens and vibrating screens, and drum screens are mostly used on gold mining ships. The determination of screening parameters must be based on the measured data of the particle size composition of gold in the original ore sand. The sieve holes selected by my country's placer gold mines are generally 10-20 mm. If a fixed chute is used as a roughing equipment, the sieve holes can be larger, but not more than 60 mm. In addition, auxiliary equipment such as washing beds and chutes are also required.

In the desludging stage, the commonly used desludging equipment is desludging buckets of various specifications. The chute gold selection allows a wide material particle size and a large processing volume, so desludging is usually not performed before the chute selection.

In the selection stage, the ore selection equipment used includes jigs, shaking tables, spiral chutes, etc., and multiple equipment are used in combination to achieve good gold selection results. Artificial ore selection requires the use of gold pans, mercury mixing cylinders, etc.

In short, the beneficiation process and required equipment of placer gold mines are the key to achieving gold recovery. With the advancement of technology and the improvement of environmental protection requirements, the beneficiation process and equipment of placer gold mines are also constantly optimized and updated to improve beneficiation efficiency and reduce environmental impact.