All slime cyanidation is one of the important methods for gold extraction. With the continuous development and maturity of the technology, the all slime cyanidation method for extracting gold is more and more popular in the gold ore dressing plants. How to extract gold concentrate by all slime cyanidation? The process flow of all slime cyanidation gold extraction can be divided into six stages: crushing and screening, grinding gravity separation, secondary classification, chip removal and pulp preparation, cyanidation leaching and desorption electrolysis. The specific process flow is as follows:

In order to improve the efficiency of the production line, a two-stage and one closed-circuit crushing and screening process is often adopted at this stage. The specific process is as follows: the raw ore of the gold mine enters the jaw crusher through the ore feeder for rough crushing. The coarse crushing products enter the vibrating screen for screening under the transportation of the belt conveyor. The ore particles meeting the requirements shall be stored in the powder bin. The unqualified ore particles are returned to the cone crusher for re crushing. After that, the discharge of the cone crusher and the discharge of the jaw crusher will enter the screening machine for treatment. Such two-stage one closed-circuit crushing and screening operation can prevent over crushing of ore and improve the working efficiency of the crusher, and at the same time, it can also separate useful minerals from gangue minerals as much as possible.

The materials stored in the powder bin enter the mill through the screw conveyor. Some of the products after grinding have realized the complete separation of concentrate and gangue minerals. In order to prevent the waste of materials caused by over grinding, the combined gravity separation process can be used to separate the gold concentrates in advance.

The specific process is as follows: the product after grinding enters the jig for primary gravity separation. The overflow part enters the pump tank for storage. The underflow part is pumped into the shaking table by the slurry pump for secondary and tertiary gravity separation. The gold particle product can be obtained after gravity separation. The remaining slurry is pumped into the desliming bucket by the slurry pump for washing.

The underflow part of the desliming bucket and the overflow part of the desliming bucket enter the pump tank for storage, and then enter the hydrocyclone for a classification operation. The overflow part is pumped into the hydrocyclone group for secondary classification. The underflow part of the hydrocyclone and the hydrocyclone group will return to the ball mill for grinding again. The former will enter the lattice ball mill while the latter will enter the overflow ball mill for grinding.

Because there are also wood debris in the pulp, in order to avoid these debris affecting the leaching effect, it is necessary to use a debris removal screen to treat the pulp. The mixing operation is mainly carried out inside. In order to meet the cyanidation reaction conditions, the concentration of the pulp should be controlled at 35% - 38%, and its pH value should be kept at 10-11. In actual production, the pulp concentration needs to be controlled by the bottom flow of the thickener and the amount of flocculant added. The pH value can be controlled by adjusting the amount of lime in the raw ore and sodium hydroxide in the thickener.

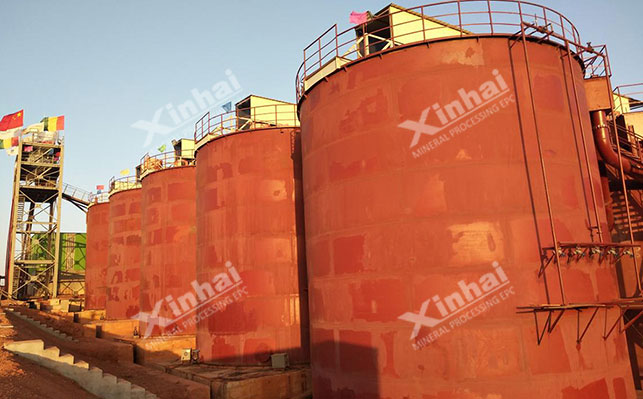

The slurry from the bottom of the thickener is pumped into the leaching tank (tank 3) by the slurry pump for pre leaching. The pre impregnation stage mainly controls CN concentration, oxygen content and inflation pressure. By adjusting each air valve, bubbles with a diameter of about 5-10mm are uniformly dispersed on the pulp surface. This process can be realized by air compressor. After the pre leaching operation, the activated carbon countercurrent adsorption stage of the pulp needs to be carried out, that is, the adsorption operation while leaching. In this stage, five leaching tanks are required to complete the carbon addition, carbon string and carbon extraction of activated carbon. After the operation of the carbon extractor, the leaching pulp flows in the opposite direction to the original pulp. The above is the completion of the pulp cyanidation leaching operation.

The desorption of gold ore is mainly carried out in the desorption column. During desorption, the washed gold loaded carbon is loaded into the desorption column, and then the aqueous solution of NaCN and NaOH is added to immerse the carbon layer. Heat the desorption column to 90 ℃ ~ 95 ℃ with an electric heater under pressure or normal pressure. After a period of desorption, desorption carbon and gold rich desorption solution can be obtained. The main method of recovering gold from gold rich desorption solution is electrolysis. The desorbed solution enters the electrolytic cell for electrolysis to obtain gold slime. The desorbed carbon can be reused by adding a certain proportion of new activated carbon after regeneration treatment.

The above is the complete process flow of all slime cyanidation of gold ore. When designing the all slime cyanidation process, the process flow, process parameters and equipment layout need to refer to the feasibility test report of the ore. Only in this way can we design a stable and reliable system to ensure production efficiency.

As a company with more than 20 years of experience in concentrator design and equipment production, Xinhai mining equipment Co., Ltd. can design the whole slime cyanidation process and customize the complete set of gold extraction equipment for you. If necessary, welcome to consult Xinhai mining equipment.