Chute gold dressing is one of the commonly used processes in placer gold dressing. The principle of the process is that the section of the equipment is in the shape of cubic parabola, and the bottom is relatively flat. During the separation process, the fine, medium and tailings gold ores are cut off at the end of the chute. This paper introduces the process and equipment of chute gold separation.

The slurry is fed into the spiral chute and flows downward along the chute surface under the action of gravity. At the same time, the slurry expands to the outer edge of the spiral chute under the action of centrifugal inertia, forming a state feature of thick outer flow layer, high flow rate, thin inner flow layer and low flow rate. The slurry flow not only flows along the longitudinal direction of the tank, but also the lateral exchange between the inner edge fluid and the outer edge fluid. The material particles are subject to the joint action of hydrodynamic force, centrifugal force, friction force and gravity. Due to the different movement directions, the material is divided into mud on the groove surface, and the minerals such as concentrate, middling, tailings and slime are distributed on the spiral chute.

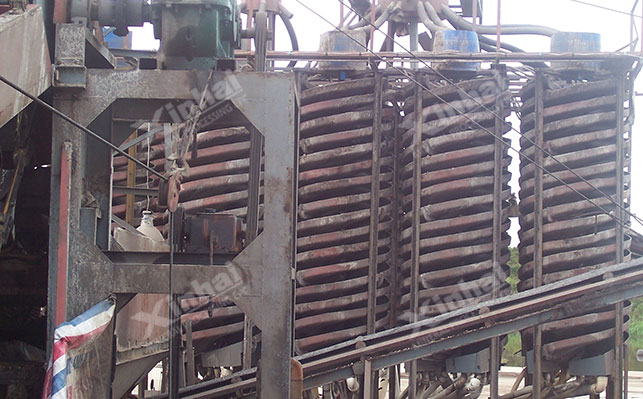

The spiral chute is suitable for processing fine-grained placer gold with low mud content. Generally, when processing placer gold, since the specific gravity difference between gold and gangue minerals is greater than 16, the spiral chute is mostly recovered in the initial stage, and the suitable particle size range of the processed materials is 0.03-0.6mm.

Spiral chute has the characteristics of large processing capacity, high enrichment ratio, simple structure design, low operation level requirements, wide range of beneficiation particle size, small unit floor area, clear ore belt distribution, easy maintenance and low investment in management level equipment. Among the beneficiation equipment, it is favored by the beneficiation workers.

The common chute equipment used for beneficiation of placer gold ore includes glass fiber reinforced plastic spiral chute, rotary spiral chute, wedge-shaped groove spiral chute, etc.

FRP spiral chute

The spiral groove of the FRP spiral chute is fixed on the structural frame. The top is provided with a separator, and the bottom is provided with a material interceptor and a hopper. According to different needs, the whole unit can be made into different layers, generally divided into one, two, three and four structures.

In addition to the separation of placer gold and other types of gold deposits, it is also suitable for the separation of rare precious metal minerals such as tantalum niobium, zircon and monazite, as well as non-ferrous metals such as ilmenite, pyrite, tin ore and rutile.

rotating spiral chute

The spiral body of the rotary spiral chute is designed with double layers (heads), and the lower transmission mechanism drives the slurry to rotate slowly. The chute section is divided into cubic parabola shape and ellipse shape, and grid bars or triangular grooves are arranged on it, which is inclined to the spiral diameter. The enhanced centrifugal force and micro vibration on the groove surface lead to the rapid zonation of materials, and the movement tracks of heavy and light minerals are clearly distinguished.

Wedge grooved spiral chute

Wedge groove spiral chute is a wedge-shaped groove carved on the chute surface. This groove can not only improve the concentration distribution on the section and enhance the water flow pulsation, but also facilitate the horizontal movement of heavy mineral particles and effectively improve the recovery of heavy minerals under the action of other mechanical parts.

If you want to know more about gold processing technology and equipment, please follow us:https://goldepcm.com