[Introduction]: An electromagnetic equipment to remove iron parts in bulk nonmagnetic materials

[Capacity]: ≤200mm

[Improvement]: Iron mover is suitable for thick materials because of the reasonable magnetic circuit design, magnetic field intensity and large magnetic penetration depth; The fully sealed structure can effectively prevent the dust and harmful gases, and has strong environment and climate adaptability and long service life.

Deep magnetic penetration;

Strong magnetically attractive force;

Resistance to dust, rain and corrosion.

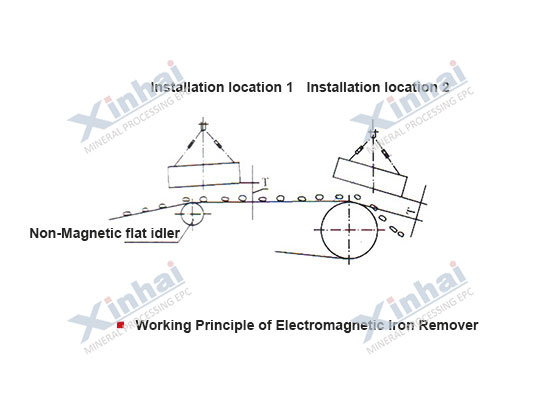

Working Principle of Electromagnetic Iron Remover: The iron remover equipped with an electric trolley is suspended above the belt conveyor for continuous operation. During the transportation of the material, the magnetism carried by the iron remover is used to attract the magnetic debris in the material, and the ferromagnetic material is mixed with the iron tape Unload the object to achieve the purpose of iron removal.

| Model | Cooling Pattern | Belt Width (mm) | Excitation Power (kW) | Hanging Height (mm) | Thickness of Materials (mm) | Belt Speed (m/s) | Weight (kg) |

| RCDA-5 | Forced Air Cooling | 500 | 1 | 150 | ≤ 100 | ≤ 2.5 | 450 |

| RCDA-6 | 600 | 1.6 | 175 | ≤ 150 | 620 | ||

| RCDA-8 | 800 | 2 | 250 | ≤ 200 | 960 | ||

| RCDB-5 | Natural Air Cooling | 500 | 1 | 150 | ≤ 110 | 400 | |

| RCDB-6 | 600 | 1.6 | 175 | ≤ 140 | 600 | ||

| RCDB-8 | 800 | 3 | 250 | ≤ 200 | 950 | ||

| RCDC-5 | Forced Air Cooling and Automatic Unloading Iron | 500 | 1.2 | 150 | ≤ 100 | 1100 | |

| RCDC-6 | 600 | 2.0 | 175 | ≤ 150 | 1300 | ||

| RCDC-8 | 800 | 3.5 | 250 | ≤ 200 | 2200 | ||

| RCDD-5 | Natural Air Cooling and Automatic Unloading | 500 | 1 | 150 | ≤ 110 | 1000 | |

| RCDD-6 | 600 | 1.8 | 175 | ≤ 140 | 1350 | ||

| RCDD-8 | 800 | 3 | 250 | ≤ 200 | 1600 |