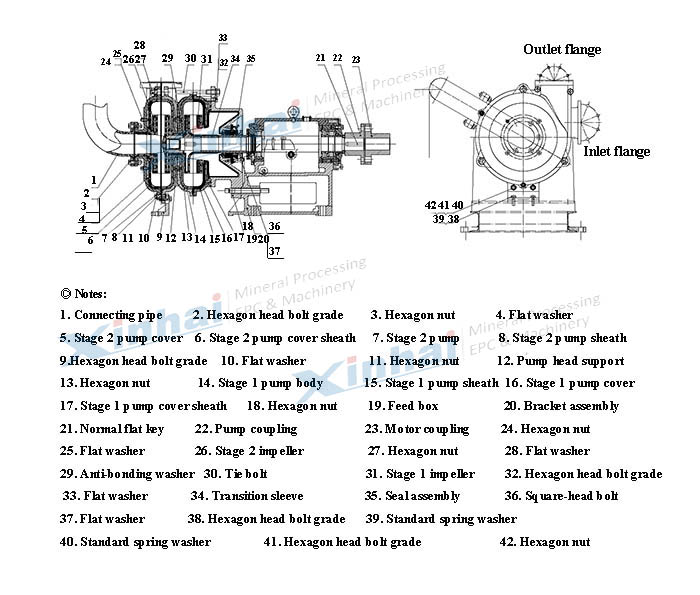

[Introduction]: A double stages slurry pump with head of 70m

[Capacity]: Flow≤203m³/h

[Improvement]: Double impellers serial design without increasing the diameter of the impeller makes head up to 70 meters

Break through the head limit (60 meters) of rubber pump, up to 70 meters;

Impellers and casings lined with Xinhai No. 35 high wear-resisting rubber, the life is 2-4 times longer than the life of metal pump;

The rubber slurry pump with resistance to wear and corrosion and high head;

Packing sealing, simple and reliable, no leakage;

It is easy to replace wet parts

The main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the grinded materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow. There are backpitch impellers in the hollow shaft, which can make the balls and coarse ores in the overflow return to the mill. With simple structure, higher operation rate, and rolling bearing, the energy conservation is significant.

| Items Model | Rotation Speed (r/min) | Flow (m3/h) | Head (m) | Max shaft power (KW) | Referenced motor (KW) | |

|---|---|---|---|---|---|---|

| Model | Power | |||||

| XPA(2)-50 | 1480 | 27.5 | 76.0 | 22.3 | Y225S-4 | 37 |

| 1480 | 41.4 | 72.2 | 22.3 | Y225S-4 | 37 | |

| 1480 | 55.2 | 66.1 | 22.3 | Y225S-4 | 37 | |

| 1480 | 69.0 | 56.0 | 22.3 | Y225S-4 | 37 | |

| 1480 | 80.0 | 43.5 | 22.3 | Y225S-4 | 37 | |

| XPA(2)-65 | 1480 | 40.0 | 76.0 | 32 | Y225M-4 | 45 |

| 1480 | 60.0 | 72.2 | 32 | Y225M-4 | 45 | |

| 1480 | 80.0 | 66.1 | 32 | Y225M-4 | 45 | |

| 1480 | 100.0 | 56.0 | 32 | Y225M-4 | 45 | |

| 1480 | 115.0 | 43.5 | 32 | Y225M-4 | 45 | |

| XPA(2)-75 | 1480 | 56.0 | 73.3 | 49 | Y250M-4 | 55 |

| 1480 | 85.0 | 69.0 | 49 | Y250M-4 | 55 | |

| 1480 | 113 | 62.5 | 49 | Y250M-4 | 55 | |

| 1480 | 150 | 51.2 | 49 | Y250M-4 | 55 | |

| 1480 | 169 | 44.0 | 49 | Y250M-4 | 55 | |

| XPA(2)-100 | 1480 | 70.0 | 73.5 | 62.5 | Y280S-4 | 75 |

| 1480 | 105 | 71.6 | 62.5 | Y280S-4 | 75 | |

| 1480 | 140 | 68.6 | 62.5 | Y280S-4 | 75 | |

| 1480 | 186 | 61.9 | 62.5 | Y280S-4 | 75 | |

| 1480 | 245 | 48.5 | 62.5 | Y280S-4 | 75 | |

| XPA(2)-100-Ⅰ | 1480 | 79.7 | 80.0 | 78.2 | Y280M-4 | 90 |

| 1480 | 119 | 78.0 | 78.2 | Y280M-4 | 90 | |

| 1480 | 159 | 74.8 | 78.2 | Y280M-4 | 90 | |

| 1480 | 211 | 67.5 | 78.2 | Y280M-4 | 90 | |

| 1480 | 279 | 52.9 | 78.2 | Y280M-4 | 90 | |

| XPA(2)-100-Ⅱ | 1480 | 58.0 | 91.8 | 64.7 | Y280M-4 | 90 |

| 1480 | 87.0 | 89.1 | 64.7 | Y280M-4 | 90 | |

| 1480 | 116 | 85.7 | 64.7 | Y280M-4 | 90 | |

| 1480 | 154 | 77.3 | 64.7 | Y280M-4 | 90 | |

| 1480 | 203 | 60.6 | 64.7 | Y280M-4 | 90 | |