[Introduction]: A wear-resistant pinch valve with excellent corrosion resistant and sealing ability.

[Capacity]: 1.6MPa/c㎡

[Improvement]: Using high wear-resistant rubber as the inner lining of the pinch valve, its abrasion resistance can reach 128%, and the service life is more than twice that of ordinary rubber, using it as the spool of the pipe clamping valve, so that the pipe clamping valve is more wear-resistant, more corrosion-resistant, and has good sealing and long-lasting use.

Manual operation is generally used for Xinhai brake valve products, according to the requirements of the users, power-driven and gas-driven operation can also be used;

Whole section: Almost no flow resistance;

Replaceable limings: The change of lining is simple, and the valve is good as new;

High sealing: Excellent elastic linings are used for sealing solid particles;

Abrasion: Produced with "the liquid nanometer formula, high-frequency curing at normal temperature" technology, the service life of the super wear-resistant rubber is 10-15 times that of the ordinary rubber, and 3-6 times that of polyurethane;

Fatigue resistance: The fatigue resistance of the rubber is strong, and the use is more durable, which has a world of difference compared with ordinary rubber;

Part of machinary protection: Only the rubber linings touch the materials which makes parts of machinary protection;

Change: The change is very convenient, and the cost is very low.

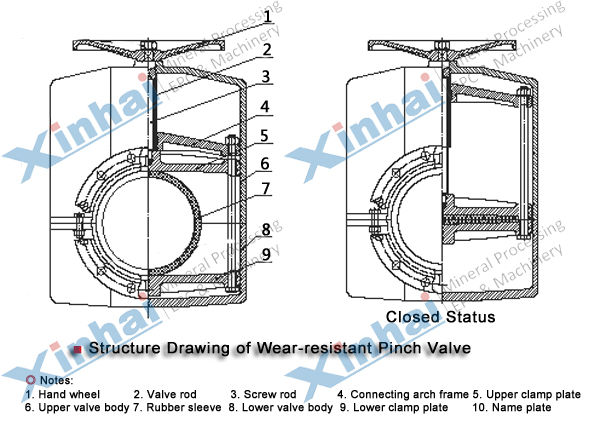

The wear-resistant pinch valve is composed of upper grip, valve body, rubber spool and lower grip.

The working principle of the pinch valve is driven by an electromagnetic solenoid, which is controlled to open and close by squeezing or loosening the hose. The medium only passes through the hose, and other parts in the valve body should not be in contact with chemically corrosive medium, and only the hose needs to be replaced. This means that the pinch valve is more economical than other types of solenoid valves.

| Specification | D | B | C | A | E | F | G | Standard Flange | Weight (kg) | |||

| Flange Diameter | Bolts PCD | Bolts Diameter | Al | Iron casting | ||||||||

| 20 | 20 | 144 | 150 | 15 | 119 | 80 | 100 | 105 | 75 | 4-Φ14 | 1.6 | 2.8 |

| 25 | 25 | 159 | 165 | 15 | 119 | 90 | 125 | 115 | 85 | 4-Φ14 | 2.3 | 3.2 |

| 40 | 40 | 199 | 205 | 17 | 119 | 118 | 162 | 140 | 100 | 4-Φ18 | 3.5 | 5.5 |

| 50 | 50 | 229 | 235 | 17 | 220 | 156 | 185 | 150 | 110 | 4-Φ18 | 6.5 | 12.5 |

| 65 | 65 | 299 | 305 | 17 | 220 | 190 | 200 | 165 | 125 | 4-Φ18 | 8.8 | 15 |

| 80 | 80 | 309 | 315 | 21 | 220 | 202 | 225 | 185 | 145 | 4-Φ18 | 10.5 | 22 |

| 100 | 100 | 354 | 360 | 25 | 220 | 247 | 269.5 | 200 | 160 | 8-Φ18 | 18.2 | 41 |

| 125 | 125 | 419 | 425 | 28 | 280 | 310 | 350 | 220 | 180 | 8-Φ18 | 29 | 66 |

| 150 | 150 | 479 | 485 | 29 | 280 | 343 | 373 | 285 | 240 | 8-Φ18 | 42 | 99 |

| 200 | 200 | 594 | 600 | 30 | 280 | 457 | 486.5 | 340 | 295 | 8-Φ22 | 87 | 230 |