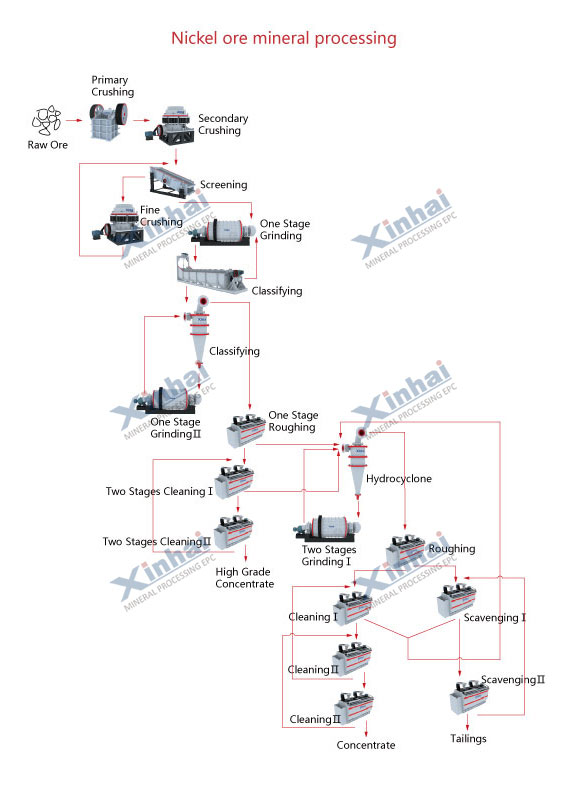

[Introduction]: Nickel ore can be divided into copper sulfide nickel ore and nickel oxide ore. Flotation is the main beneficiation method when processing copper sulfide nickel ore, and magnetic separating and gravity separating are the commonly auxiliary methods.

[Application]: Nickel ore beneficiation can be applied to process copper nickel ore accompanied by pyrite and other gangue or nickel oxide ore.

The mixing flotation process is to separate nickel ore in which copper has lower content than nickel. The mixed concentrate of copper and nickel will smelt into high grade nickel directly.

Copper nickel can be get from raw ore, then the copper concentrate with low grade nickel and the nickel concentrate with low grade copper can be separate from the mixing concentrate, and the nickel concentrate will be sent into the next stop-smelting, nickel matte can be get then separated.

When floatability differences happens to the various nickel element of the raw ore, then nickel ore can be recoveried further from tailings after the copper and nickel been mixing flotation.

When process copper-sulfide nickel ore, collector and frother will be used in order to better results. A basic principle of copper-sulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite. For it is easier to recovery cooper from nickel concentrate. The process has a vital advantage-receive copper concentrate with low grade nickel directly.

As the exploration got deeper, the original 300tpd silver cyanide plant was no longer able to meet the process needs. Due to the shortage of equipment maintenance and the inappropriate process, the plant capacity fell short of expectations and silver recovery dropped year by year. So the client decided to upgrade the plant. The raw ore consisted of metallic minerals (native silver, pyrite and limonite) and gangue minerals (quartz, feldspar and clay), with silver being the valuable mineral. ...

In recent years, the new energy market has risen rapidly, and the development momentum of lithium mines is booming. At the beginning of the year, Sinomine Resources Group Co., Ltd. acquired Bikita lithium mine in Zimbabwe for 1.146 billion yuan, which attracted great attention from the market.At the beginning of June 2022, Xinhai successfully signed a 2 million TPA lithium project in Zimbabwe with Sinomine to help its overseas lithium mine construction! ...