Activated carbon adsorption gold extraction method is a commonly used gold extraction process, which uses the characteristics of activated carbon to adsorb gold to recover gold. Here are the steps of this gold extraction method and the commonly used gold extraction equipment.

Activated carbon for gold adsorption

1. Use activated carbon to adsorb and leaching gold from cyanide pulp or solution to produce carbon loaded with gold;

2. Desorb the gold-loaded carbon to complete the returning of gold into the solution and obtain gold pregnant liquid;

3. Use various methods to recover gold from gold-containing pregnant liquid;

4. Regenerate the desorbed lean carbon, restore its activity, and return to the adsorption operation for reuse.

1. Leaching agitation tank

The function of the leaching agitation tank is to stir and drag the ore pulp to form a uniform suspension mixture, which is suitable for gold leaching, adsorption, and other mixing operations. Usually, the ore particle size of -200 mesh accounts for more than 90%, and the pulp concentration is less than 45%.

2. Desorption electrolysis system

In the desorption system, anions that are easily adsorbed by activated carbon are added to replace Au(CN)2- to finish the desorption of gold. The pregnant solution obtained by desorption of gold-loaded carbon is recovered by ionization method to obtain solid gold.

3. Zinc powder replacement device

For gold ore containing more silver, after the pregnant liquid is purified and deoxidized, a zinc powder replacement device is added to obtain gold mud.

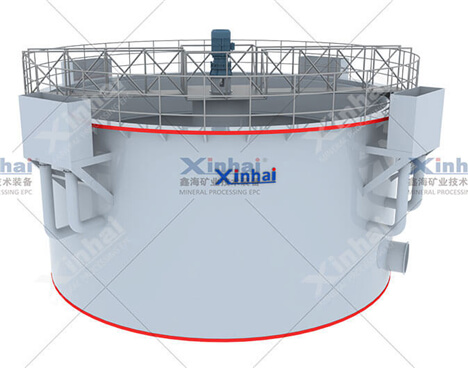

4. Washing thickener

The washing thickener is a special equipment for the solid-liquid separation and washing operation of the pulp after cyanidation leaching. Besides, it can be used for the dewatering of uranium mines in hydrometallurgy, light industry and chemical industry.