The price of iron ore has risen recently. With the change of the international situation, iron ore has been pushed into hot discussion. More and more friends consult with iron ore concentrators. Have you considered the problem of waste residue treatment after beneficiation? Here we recommend an iron tailings thickener. Taking the thickener with a diameter of 30 meters as an example, we will introduce its advantages and technical parameters.

Although beneficiation provides a lot of material resources for the society every year, its environmental damage cannot be ignored, and the pollution of the concentrator mainly comes from the discharge of waste water and slag. Tailings dry discharge is one of the effective ways to solve tailings pollution at present, which can reduce the damage of tailings to farmland, deep forests, water, soil and air. The iron tailings thickener can be used for thickening and dewatering in the tailings dry discharge process, and cooperate with the hydrocyclone equipment to complete the tailings dry discharge.

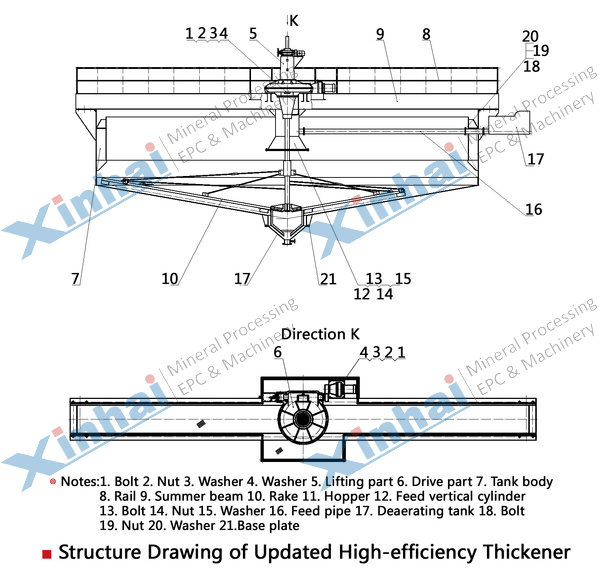

The 30m thickener refers to the thickener with an inner diameter of 30m. The thickener produced by Xinhai can be made from 2.5 meters to 50 meters in diameter, and 30 meters is a medium model. In the dry discharge process of iron tailings, the iron tailings are first sent to the hydrocyclone for concentration, the overflow of the hydrocyclone is sent to the iron tailings thickener for sedimentation separation, and the underflow is sent to the filter press to make filter cake.

The processing capacity of the 30m thickener is 1500-1800t/d, that is, a 30m thickener can process 1500-1800t iron tailings every day, with a large processing capacity. The floor area of the 30 meter thickener is also a topic of great concern to friends, with a sedimentation area of 706 m2. Other technical parameters can refer to the following table:

| model | Inner diameter of thickener(m) | Pool center depth(m) | Sedimentation area(m2) | Rake frame time per revolution(min/r) | Rake lifting height(mm) | Handling capacity(t/d) | Drive power(kW) |

|---|---|---|---|---|---|---|---|

| NZY-30 | 30 | 4.5~5.5 | 706 | 10~14 | 450 | 1500~1800 | 11 |

The above introduces the parameters of the 30 meter iron tailings thickener and the importance of tailings dry discharge. Those who hope to have iron ore concentrators should also fully consider the value of tailings to maximize the benefits.