Washed kaolin has the characteristics of strong hiding power, high whiteness and uniform particle size distribution. It is widely used in the paper industry and can well improve the printability, ink absorption and smoothness of paper. So what is washed kaolin? What are the purification methods and uses of washed kaolin?

Kaolin got its name from the discovery of Gaoling Mountain in Jingdezhen, China. Natural kaolin cannot be directly used in porcelain making, paper making, coating and other industries because of its high impurities. Therefore, natural kaolin should be processed. According to the different processing methods, it can be divided into two kinds: washed kaolin and calcined kaolin. Therefore, water washed kaolin is a kind of deeply processed kaolin.

Compared with calcined kaolin, washed kaolin has the characteristics of low processing cost and wide application, but its whiteness is slightly poor. Generally speaking, the whiteness of calcined kaolin will increase significantly, while the whiteness of washed kaolin will not increase significantly.

Water washed kaolin purification process flow: after crushing the raw ore, it goes through pulping, desanding, cyclone classification, peeling, centrifuge classification, magnetic separation (or bleaching), concentration, filter pressing, and drying.

The raw kaolin (rock) ore is made into slurry, which makes the mineral dissociate in water in the form of granular monomer, most of which are micron sized fine particles. In order to remove the charge attraction on the particle interface, an appropriate amount of dispersant is added to make the slurry concentration 5%~14%, and the mineral particles in the slurry can be fully dispersed under the action of gravity. The principle is based on Stokes' Law, that is, when a spherical object falls in a viscous body due to gravity, the falling speed is a constant and proportional to the square of the radius of the spherical object.

This method is mainly used to remove detrital minerals such as quartz, feldspar and mica, and coarse impurities such as rock debris. At the same time, it can also remove some iron and titanium minerals to improve the whiteness, but not much, generally not more than 90%.

At present, the flotation processes applied to kaolin mainly include the following.

(1) Selective flocculation

The process of selective flocculation is relatively simple. First, the solid particles in the suspension are fully dispersed, and then flocculants are added to selectively adsorb the target minerals (mineral particles or gangue fine mud). After the flocculation of the target mineral is completed, the flotation method is used to separate the floc from the dispersed phase.

(2) Carrier flotation

Carrier flotation is to use the ore particles of general flotation particles as the carrier, so that the target mineral fines are covered on the carrier for flotation. The carrier flotation can reduce the TiO2 content to below 0.8%. The carrier can be either of the same kind or of different kind.

For example, sulfur is used as the carrier of fine apatite flotation; Pyrite is used as carrier to float fine gold; Calcite is used as a carrier to float impurities such as anatase in kaolin; There are also Fe2O3 adsorbed in kaolin by limestone as carrier in China. Among them, calcite is a widely used carrier mineral with good floatability and is easy to be removed in the form of foam.

(3) Double liquid layer flotation

The principle of double liquid layer flotation is to use the difference of solid (ore particles) - liquid (water) - oil three-phase interfacial tension, and different ore particles have different hydrophobic degrees between three-phase interfaces, so they will enter different interfaces or phases, so as to achieve the purpose of separation.

The selective enrichment of mineral particles at the oil-water interface is the theoretical basis of double liquid layer flotation. By adding a certain collector, the mineral surface wettability and three-phase interfacial tension can be adjusted, so that fine minerals can be enriched at the oil-water interface, or ore particles can be extracted into the organic phase.

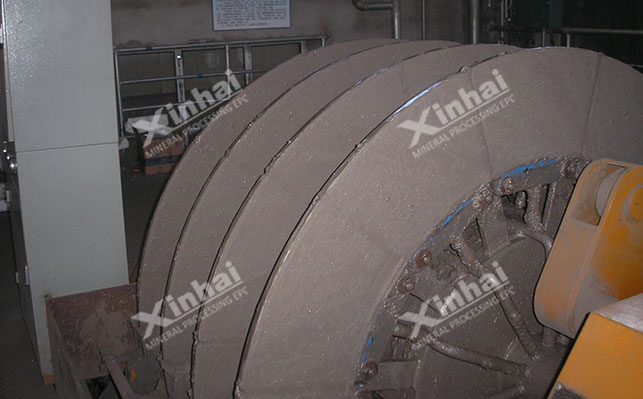

Dyed mineral impurities (such as siderite, pyrite, limonite, hematite, ilmenite, rutile, etc.) in kaolin are weakly magnetic, so magnetic separation is generally required for the desanded kaolin.

Because most of the iron and titanium minerals in kaolin are embedded with fine particle size, the removal rate of high intensity magnetic separation is usually not high. Therefore, high gradient magnetic separators are mostly used in the industry for magnetic separation of kaolin. High gradient magnetic separation refers to the use of small magnetic media under a high background magnetic field (generally 1~2T) to generate a high magnetic field gradient (i.e. a high magnetic force) on its surface, so as to achieve the magnetic separation purpose that cannot be achieved by general magnetic separation.

Washed kaolin is the raw material for producing high-grade porcelain; After deep processing and modification, the products can become ideal raw materials for paper making, rubber, paint, paint and other industrial sectors. Recently, ceramics, rubber, plastics, artificial leather, white cement, refractory materials, chemicals and other industries as well as agriculture are widely used. With the further improvement of the mineral processing technology of kaolin, the application scope of kaolin will be increasingly extensive.

The original soil of water washed kaolin has cohesiveness and can be directly used as refractory binder or paper filler. As far as paper filler is concerned, the whiteness of calcined kaolin is not less, and the cost is relatively high.

The above introduces the water washed kaolin, the purification method of kaolin, and the use of water washed kaolin. With the continuous progress of the beneficiation and purification process, the purity and whiteness of kaolin have been greatly improved, and the application fields are more and more extensive. If you are looking for a professional kaolin purification manufacturer, please contact Xinhai!