High purity talc can be used as medicine or cosmetics. For high grade talc ore, simple mineral processing methods such as manual separation method, electrostatic method and photoelectric method can be used to obtain high grade talc. However, for low-grade talc ore, the beneficiation process will be slightly more complex. The wet beneficiation process is recommended here, which has good beneficiation effect for low-grade talc ore.

For low-grade talc ore, wet beneficiation is generally required to improve the grade. Wet beneficiation includes flotation method and scrubbing method.

Wet beneficiation process flow: firstly, the ore needs to be broken and ground to separate the talc and associated mineral monomer, and then the wet grinding is usually carried out in the lattice ball mill.

The wet milled talc (90%~95% of the talc with particle size less than 0.074mm generally) can enter the flotation process. The method is as follows: make the talc into slurry with a concentration of 15%~20%, send it to the mixing tank to add flotation agent, and then send it to the flotation machine. At the same time, blow air into the machine, and the air is dispersed in the pulp as small bubbles. Due to the role of flotation agent, the talc is attached to the bubbles, and floats on the surface of the pulp to become foam. After being scraped out with a scraper, it is the concentrate. The concentrate becomes the final product after being concentrated, filtered, dried and packaged.

The residual impurities in the flotation machine are discharged from the bottom. As talc is completely symmetrical in crystal structure, it is a non-polar molecule. Its surface is hydrophobic, while the surface of other minerals associated with it is hydrophilic. With the addition of flotation agent, talc can be successfully separated from concentrate by flotation.

There are different types of flotation agents for flotation of talc:

1). Collector, such as kerosene; Foaming agent, such as No. 2 flotation oil, methyl isobutyl methanol (MIBC for short);

2). Activator, such as sulfuric acid;

3). Inhibitor, usually lime

4). The pH regulator of pulp is sulfuric acid and lime.

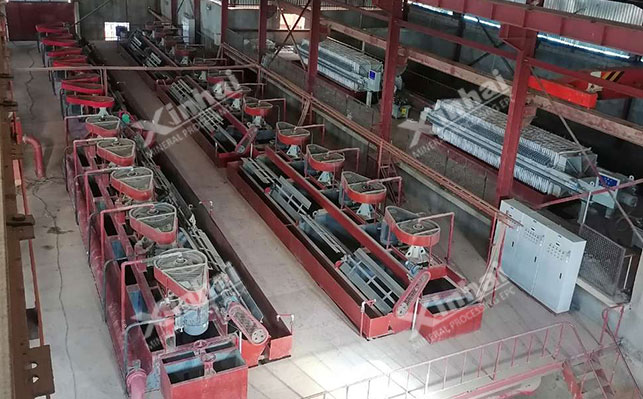

Flotation machinery is generally composed of tank, agitator and aeration device. According to the different aeration devices, flotation machines can be divided into mechanical agitation type and aeration type. The mechanical stirring flotation machine commonly used in China is XJK or A type. The flotation column is a pneumatic flotation machine.

The flotation process of talc is relatively simple, and the final concentrate can be obtained only by one roughing, one scavenging and 2-4 cleaning.

Talc scrubbing beneficiation is another method in wet beneficiation, which is completed by scrubber and hydrocyclone, including grinding, scrubbing, sedimentation, concentration, centrifugal dehydration and drying processes. This method is relatively simple, but it is not widely used at present. The product recovery rate of this method is low.