The rapid rise of the new energy market has driven the growth of lithium metal demand. At the same time, the ores that can extract lithium metal have also become the new favorite of the mineral processing industry. Common minerals for extracting lithium include spodumene, lepidolite, etc. This paper will mainly introduce the process of extracting lithium from spodumene and the equipment used in the beneficiation process.

Hand selection is a method for preliminary screening and pre selection of spodumene before it is officially classified. It is generally completed in the crushing section. The crushed ore with a width of no more than 1200mm is sent into the hand selection belt. Through its appearance, color, glossiness and other conditions, manual selection is carried out to select 25~300mm spodumene. The hand selection belt speed is generally controlled at 0.2~0.4m/s.

The manual separation method has low technical requirements and simple operation process. It does not require special sites and equipment. It can only be carried out on a simple manual separation belt or manual separation console, which can preliminarily separate the ore from gangue and improve the ore dressing grade. However, manual selection requires high labor intensity, low production efficiency and large waste of resources.

The mineral processing equipment of manual concentration process includes crusher and belt conveyor

Pre desliming is also called pre floatation desliming. It is mainly to conduct flotation desliming for spodumene before flotation and heavy medium beneficiation. The process is to grind the ore to -0.074mm, accounting for 75%, and use dodecylamine or coconut amine as gangue mineral collector to remove slime and mica by flotation.

The pre desliming process is due to the existence of a large amount of ore slime in the spodumene flotation system, which will not only affect the flotation effect, but also increase the dosage of reagents. By pre desliming, the grade of lithium ore can be effectively improved; Reduce the loss of lithium in the form of lithium mica; Mica impurities can be effectively removed under the condition of coarse particles to reduce grinding energy consumption.

The beneficiation equipment of pre concentration and desliming process includes: dry ball mill, coarse particle flotation machine, reagent agitation tank

Flotation is the main application method of spodumene beneficiation at present, in which spodumene with relatively pure surface is easy to be floated by oleic acid and its soap. For spodumene whose surface is polluted by weathering or contaminated by slime in pulp, due to the existence of harmful ions, it needs to be separated by positive flotation or reverse flotation with cationic collectors in a strong alkaline environment.

Spodumene positive flotation: under strong alkaline environment, oleic acid and its soap salts are added as collectors, while sodium silicate generated by the addition of sodium hydroxide and the silicate in the pulp can be used as inhibitors, which can directly float spodumene, leaving gangue minerals in the flotation cell.

Spodumene reverse flotation: lime is adjusted to an alkaline environment, dextrin, starch, etc. are added as inhibitors to prevent spodumene from remaining in the tank. Sodium oleate+oxidized paraffin soap, etc. are used as collectors to float silicate gangue ore and complete reverse flotation. If the mineral contains iron, HF resin acid salt can be added as a foaming agent to further remove iron impurities.

The beneficiation equipment of flotation process includes XCF flotation machine, KYF flotation machine, SF flotation machine and JJF flotation machine.

The heavy medium separation method is suitable for processing spodumene with fine embedded particle size. There is a certain density difference between this kind of mineral and other gangue ores. Then, the pressure of 0.05~0.20Mpa is used to feed into the heavy medium cyclone for separation. The bottom flow part is spodumene, which becomes spodumene concentrate after being removed by the media removal screen. The overflow is gangue ores (quartz, feldspar, biotite, etc.) which become tailings after being removed by the media removal screen.

The mineral processing equipment of heavy medium separation process includes: heavy medium cyclone

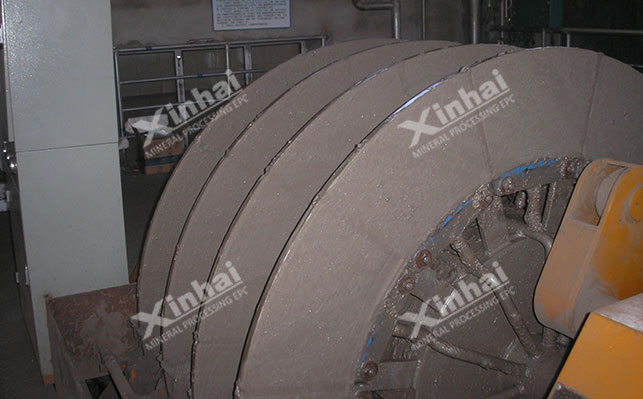

Magnetic separation is mainly used to deal with iron impurities in spodumene. Due to its weak magnetism, it is necessary to remove iron impurities through strong magnetic separation to obtain low iron spodumene concentrate. The magnetic separation method is used to separate spodumene, which is simple in operation, easy to control, and has strong adaptability. When a single magnetic separation cannot effectively remove iron, the combined method can be used to complete the iron removal operation.

The main application equipment of magnetic separation method is: wet high intensity magnetic separator, high gradient magnetic separator, etc.

The combined beneficiation method is mainly used to separate some spodumene with complicated associated components, and the single beneficiation method cannot effectively recover lithium concentrate minerals. Therefore, separation can be achieved through combined beneficiation methods, such as flotation magnetic separation combined process, flotation gravity magnetic separation combined process, flotation chemical treatment combined process, etc.

The equipment that can be used in the combined beneficiation method includes flotation machine, magnetic separator, jig, shaking table, spiral chute and leaching tank.

All the processes for extracting lithium from spodumene have been listed. In actual production, it is rare to extract lithium concentrate by a single process, and the combined beneficiation process is usually used. Therefore, the determination of spodumene lithium extraction process should first be conducted with mineral processing test, and the determination of the process based on the results of mineral processing test is more scientific and has better effect.