Graphite is an important non-metallic mineral. After purification, it can be used in optics, energy, aerospace, environment, new materials and many other fields. Therefore, it has important strategic significance for its beneficiation and purification.

Quartz, illite, kaolinite, andalusite, sericite and a small amount of pyrite, limonite, tourmaline, calcite, etc. are often associated with graphite ore, which can only be used after purification and impurity removal. Common graphite purification methods include selective flocculation, flotation, alkali acid, acid leaching, chlorination roasting and high-temperature roasting.

To purify graphite ore by selective flocculation, it is necessary to add macromolecule flocculant into the suspension containing two or more components, so that the flocculant can selectively adsorb a certain component in the suspension, and produce flocculation precipitation through the bridging action, so as to achieve the purpose of component separation.

The main flocculants are sodium silicate, sodium hexametaphosphate, lignin starch, carboxymethyl cellulose and sodium silicate as dispersants, and cassava powder, acorn powder, sodium alginate and polyacrylamide as flocculants to purify graphite ore.

The graphite ore selective flocculation purification method and equipment are relatively simple and low cost, but the fixed carbon recovery rate is low, only about 40%.

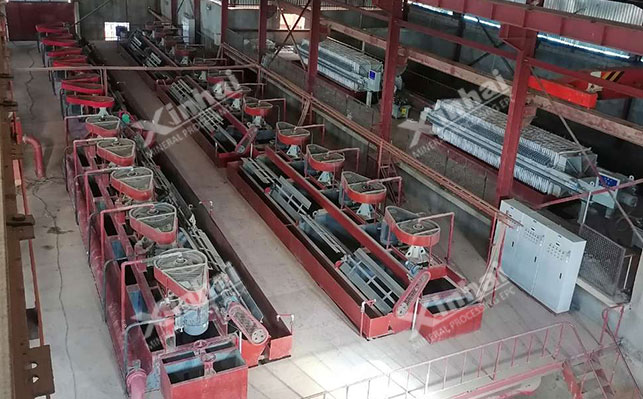

Flotation is a common method for graphite ore purification, mainly by adding a series of flotation reagents to enrich the target minerals selected in the gas-liquid interface, so as to achieve the separation from impurities and achieve the purpose of purification.

Graphite itself has good natural floatability and hydrophobicity, so conventional graphite ores can be purified. In the purification process, in order to protect the large scale of graphite, the process flow of multistage grinding, multiple beneficiation and regrinding and re concentration of coarse concentrate is generally adopted.

Coal tar is often used as collector in graphite ore flotation, terpinyl alcohol oil or butyl ether oil as foaming agent, and sodium silicate and sodium fluosilicate as inhibitors.

The grade of graphite can reach 80%~90%, even about 95%, through the purification of graphite ore by flotation, and the method has low drug consumption, low energy consumption and low cost. However, when the graphite ore is mixed with extremely fine silicate minerals and compounds of potassium, calcium, sodium, magnesium, aluminum and other elements, the monomer dissociation cannot be achieved in the grinding stage, and other processes need to be used for purification after flotation.

At present, the acid alkali method is a relatively mature process to purify graphite ore, which can be divided into two processes: alkali melting and acid leaching.

Alkali melting process: under high temperature conditions, the alkali in the molten state reacts with the acidic impurities (silicate, aluminosilicate, quartz) in the graphite to generate soluble salts, and then the impurities are removed by washing.

Acid leaching process: use acid to react with metal oxide impurities, convert some unreacted impurities in the alkali melting process into soluble salts, and then remove impurities by washing method to separate them from graphite, so as to improve the purity of graphite.

The grade of graphite can reach 99.5% by alkaline acid purification of graphite ore, and the equipment is simple, energy consumption is low, and one-time investment is small. However, the acid and alkali of this method will have strong corrosivity to the equipment, and the wastewater after purification will be seriously polluted. In addition, there is the disadvantage of graphite loss.

There are sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid and other methods to purify graphite ore by acid leaching. Among them, sulfuric acid and hydrochloric acid are more suitable for leaching, with strong leaching capacity, but some sulfates have low solubility and hydrochloric acid has high price; Nitric acid has strong oxidation and volatility, and it is easy to decompose under light and produce highly toxic phosgene, which is easy to explode under high temperature; Hydrofluoric acid cannot undergo oxidation reaction or reduction reaction. The key point is that it can effectively dissolve SiO2 and silicate. After fully mixing graphite and hydrofluoric acid, hydrofluoric acid will react with impurities in graphite to generate water soluble compounds and volatiles, and then remove the soluble impurities through water washing to obtain high-purity graphite.

Hydrofluoric acid purification of graphite ore can effectively remove impurities in minerals with low energy consumption. However, this method is highly toxic and causes great environmental pollution.

The chlorination roasting method is mainly used to purify graphite ore by adding an appropriate amount of reducing agent into the graphite ore, and then roasting at high temperature under specific atmosphere and equipment, so that the valuable metals in the mineral can be combined with chlorine and transformed into gas phase or condensed phase metal chloride with low melting point and boiling point, thus separating effectively from other components and obtaining high-purity graphite.

The chlorination roasting method has the advantages of high efficiency, low energy consumption and low cost. However, chlorine gas in this method has strong corrosivity and toxicity, causing great environmental pollution.

The melting point of graphite ore is very high (melting point is 3652 ℃, boiling point is 4250 ℃), which is much higher than other impurity minerals. The high-temperature calcination method is used to purify graphite by making use of the difference in the melting point of graphite. The graphite ore is heated to 2700~3000 ℃. Most of the impurities have been gasified, so the graphite can be effectively separated from the impurities.

The purification of graphite ore by high-temperature roasting can achieve a grade of 99.99% or even higher, but it requires large energy consumption, high equipment requirements, and certain requirements for the purity of raw graphite ore.

The above are six common beneficiation methods for graphite ore. As for which one to choose, it needs to be determined according to the ore properties of graphite ore, concentrator conditions, investment budget and other factors. It is suggested that the graphite ore should be selected first, and the purification process should be selected according to the test report to achieve ideal technical and economic benefits.