Lithium, known as the new energy metal in the 21st century, is one of the important raw materials in the new energy battery industry. From spodumene to battery grade lithium carbonate that can be used in batteries, many processing processes need to go through. The first step is to process spodumene into lithium concentrate. In recent years, Xinhai has undertaken a number of lithium ore processing projects and accumulated rich experience in processing spodumene into lithium concentrate. It is recommended that you use the flotation - magnetic separation combined process to obtain higher grade lithium concentrate. The process flow is described in detail below.

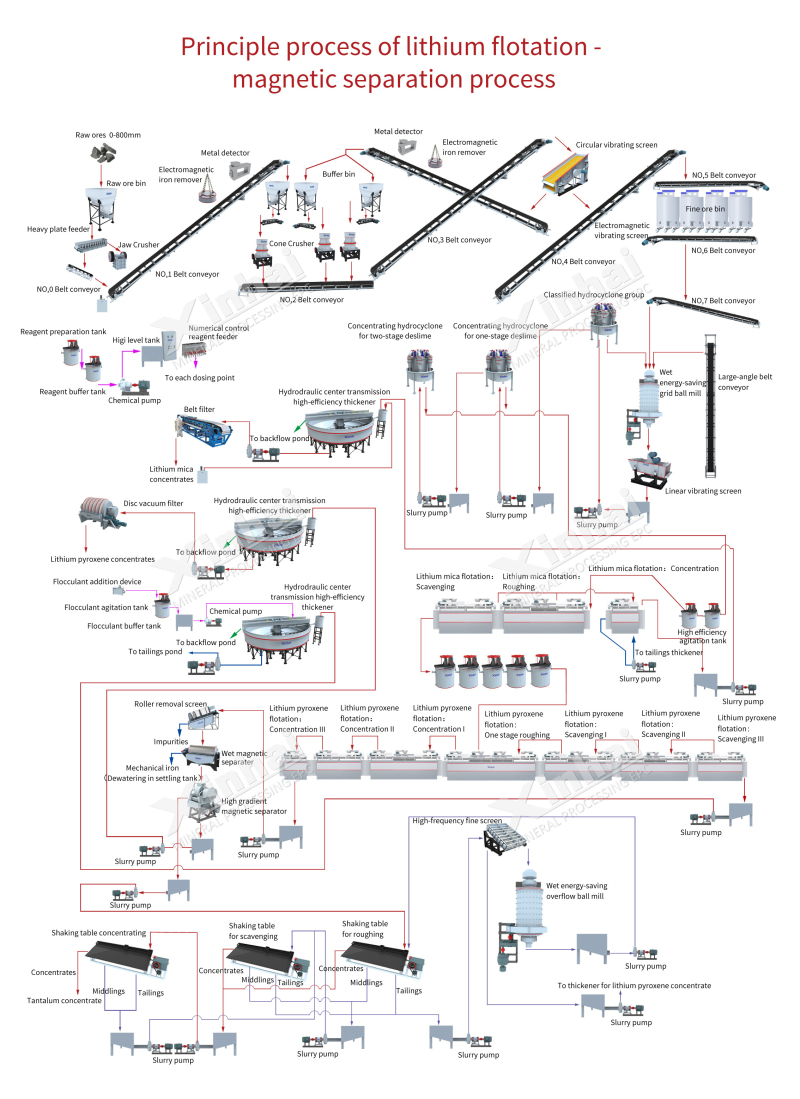

Crushing and screening: 0-800mm spodumene raw ore is roughly crushed by a jaw crusher, and then sent to a cone crusher for medium and fine crushing. The ore screened by a circular vibrating screen is returned to the cone crusher, and the minerals under the screen are sent to the fine ore bin for grinding;

Grinding and classification: spodumene in the fine ore bin is first classified by a classification hydrocyclone, and the ore to be grinded is sent to a wet energy-saving grid type ball mill for one-stage grinding, and after grinding, the slurry pump is sent to a concentrated hydrocyclone for two-stage desliming;

Lithium mica flotation: in the flotation stage, the lithium mica flotation is carried out first, and the full mixing of ore, medicine and gas is completed in the high-efficiency stirring tank, and then sent to the flotation machine for one sweep, one coarse and one fine, and the lithium mica is produced by flotation. The concentrate is sent to the high-efficiency thickener by the slurry pump for sedimentation treatment, and then filtered by the belt filter, and finally the lithium mica concentrate is obtained; Intermediate ore and tailings enter the following lithium concentrate flotation process.

Spodumene flotation: lithium concentrate flotation adopts the flotation process of one coarse, three sweeps and three concentrates. The flotation concentrate is sent to the high-efficiency thickener for sedimentation by the slurry pump, and then filtered by the disc vacuum filter to obtain spodumene concentrate. The middlings and tailings will enter the magnetic separation stage after the impurities are removed by the drum screen;

Magnetic separation: in the magnetic separation stage, after the slurry is separated by wet magnetic separator and high gradient magnetic separator, the concentrate is sent to the high-efficiency thickener for sedimentation by the slurry pump, and then filtered by the disc vacuum filter to obtain spodumene concentrate. The middlings and tailings are sent to the wet overflow ball mill for secondary grinding. The grinded slurry is re-selected by the shaking table to select useful minerals. In this case, tantalum concentrate is selected.

After the above steps, we obtained lepidolite concentrate and spodumene concentrate respectively. The concentrate can be sold directly, with higher price than the raw ore and considerable income. It can also continue to be processed into lithium carbonate or battery grade lithium carbonate. For this part of the process flow, please refer to the article: spodumene production lithium carbonate process flow. Since our company is not involved in subsequent process operations, we only give a brief introduction.

The combined process of spodumene processing flotation and magnetic separation can effectively improve the grade of lithium concentrate and improve the recovery rate of beneficiation. The 2 million TPA lithium ore project in Zimbabwe undertaken by Xinhai is based on the combined process of flotation and magnetic separation. The final result is very satisfactory to the customer. At the beginning of 2023, it further increased the investment.

Of course, the nature of ore is different, and any applied beneficiation scheme is not advisable. Xinhai has always adhered to the principle that there are no identical two mines in the world, and the formulation of any scheme is based on the results of beneficiation tests and combined with the professional suggestions of several beneficiation experts. Xinhai can provide you with the mining industry chain service of processing spodumene into lithium concentrate. If you need, please contact our online customer service.