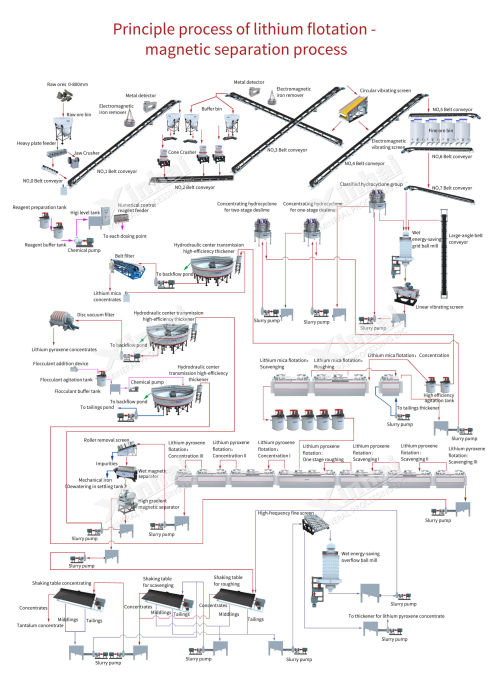

Different lithium ores have different properties, and the content of lithium oxide in minerals is low, and the mineral composition is different, so the processing methods of lithium ores are also different. At present, the common lithium ore beneficiation processes mainly include flotation, magnetic separation, heavy medium beneficiation and combined beneficiation. The lithium ore beneficiation process flow chart designed by Xinhai Mine is mainly suitable for processing spodumene and lepidolite lithium minerals.

After grinding, lithium ore is added with strong alkali for flotation. After high concentration, strong stirring and repeated scrubbing and desliming in alkaline medium, oleic acid and its soap salts are added as collectors to directly flotation lithium concentrate, leaving gangue minerals in the tank.

The alkaline environment is mainly created by lime, and starch, dextrin, etc. are added to inhibit the flotation of lithium ore. At the same time, cationic collectors are used to float silicate gangue minerals to the surface of the pulp for discharge. In case of iron-containing minerals, foaming agents such as HF and resinate can be added to remove iron.

It is mainly used to treat minerals containing iron impurities in lithium ores. These minerals have weak magnetism and need to be removed by strong magnetic separation to obtain low iron spodumene concentrate.

For spodumene with relatively coarse crystal size, the heavy medium beneficiation method can be used to make lithium ore become a heavy mineral product. Generally, the lithium ore after ore washing and desliming is mixed with heavy medium (heavy medium includes heavy liquid and heavy suspension, which mainly refers to heavy suspension), and the lithium concentrate can be selected by feeding it into the heavy medium cyclone at a pressure of 0.05-0.20Mpa for separation.

In this process, oxidized paraffin soap and naphthenic acid soap are used as combined collectors, NaOH is used as pH regulator, and a flotation process of one coarse and one fine is used in alkaline pulp to obtain spodumene concentrate, and then iron is removed by high intensity magnetic separation to obtain spodumene concentrate with low iron content.

After slurry mixing, the ground material enters the gravity concentration stage (removing tantalum, niobium and other products). After the gravity concentration tailings are concentrated and deslimed by the thickener, the slurry is mixed by adding oleic acid and oxidized paraffin soap, and spodumene concentrate is flotation under high alkalinity conditions, and then the iron impurities are further removed by high intensity magnetic separation for purification.