As a precious and rare metal, gold is loved by many people and is a symbol of wealth. Where does gold come from? In fact, gold is extracted from gold mines. Gold mines refer to gold-bearing mineral bodies. The types of gold deposits are complex and diverse. And gold extraction processes vary from their gold mines’ properties. Here is the principle and process of activated carbon gold extraction process.

The activated carbon gold extraction process utilizes the adsorption capacity of activated carbon for gold. Here, a leaching and agitation tank is required. The number of tanks needs to be determined according to the processing capacity. Usually, 7-9 tanks are subsidized in steps. The gold-containing pulp is poured downward from the high tank at the top of the step, while the activated carbon is adsorbed upward from the tank at the lower end of the step. The activated carbon is separated in the carbon screen to prevent the activated carbon from falling down with the slurry, so that the pores of the activated carbon adsorb the gold concentrate. After that, the desorption electrolysis device is used to electrolyze the gold adsorbed activated carbon to complete the whole process, and the gold concentrate is separated and desorbed.

1. Crushing and grinding

Gold ore is generally a large piece of ore. In order to better dissociate gold from gangue minerals, it is necessary to crush and grind large pieces of gold ore. At this time, the equipment that needs to be used includes jaw crusher, linear vibrating screen, ball mill and classifying equipment. Hydrocyclone and classifiers are used as classifying machines according to the processing capacity.

2. Cyanidation leaching

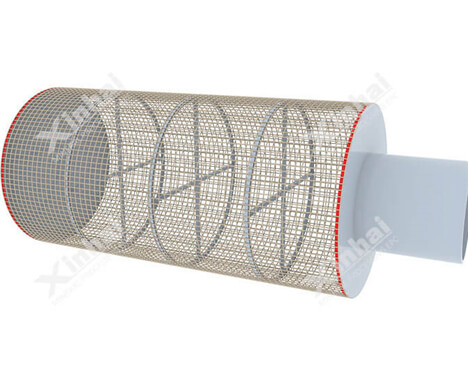

The cyanidation of gold ore pulp is carried out in the first two leaching tanks, and the cyanidation is carried out in the following 5-7 tanks while adding activated carbon for countercurrent adsorption. At this time, the equipment to be used mainly includes leaching agitation tank and carbon screen.

3. Carbon adsorption

This link generally requires the addition of activated carbon. There are many types of activated carbon. Coconut shell activated carbon is a good choice, which uses the characteristics of activated carbon to absorb gold and silver to dissolve and adsorb gold ions to form gold-loaded carbon.

4. Dewatering and agitation

The equipment used in this link includes hydraulic filter press, high-efficiency high-frequency dewatering screen, etc. This process designed by Xinhai can reduce the wear and tear of activated carbon, save power consumption by more than 70%, and evenly suspend solid materials, effectively improving the gold recovery rate.

5. Desorption electrolysis

In this link, the gold-loaded carbon enters the desorption electrolysis device, and a mixed solution of sodium cyanide and sodium hydroxide is added at the same time, in order to desorb and electrolyze the gold in the gold-loaded carbon at high temperature. This process has certain requirements on temperature and pressure, the temperature needs to reach 150 ℃, and the pressure reaches 0.5Mpa. This design has the characteristics of fast desorption and ideal effect, which can desorb 99% of gold within 2-6 hours.