Gold is a precious metal. With the continuous improvement of global living standards, the world has seen a significantly increasing demand for gold. At present, the main gold beneficiation methods mainly include: gold flotation method, gold CIL method, gold CIP method and gold heap leaching method. Here we introduce the differences between gold heap leaching method and gold flotation method.

We mainly analyze the differences between these two gold processing methods for you from three aspects: application field, process flow and required equipment, in order to help you quickly choose a suitable gold beneficiation method.

For gold ore heap leaching and gold ore flotation method, the application fields should be fundamentally different. Gold flotation is mainly used in rock gold ores, and is often used to treat gold-bearing sulfide minerals with high floatability. Flotation method is widely used in China now. It can be said that more than 80% of rock gold mines in China are selected by flotation method, because flotation process has a series of advantages. It can enrich gold into sulfide minerals to a greater extent, and the gold content in tailings is so low so it can be directly discarded. Besides, the beneficiation cost of flotation process is low.

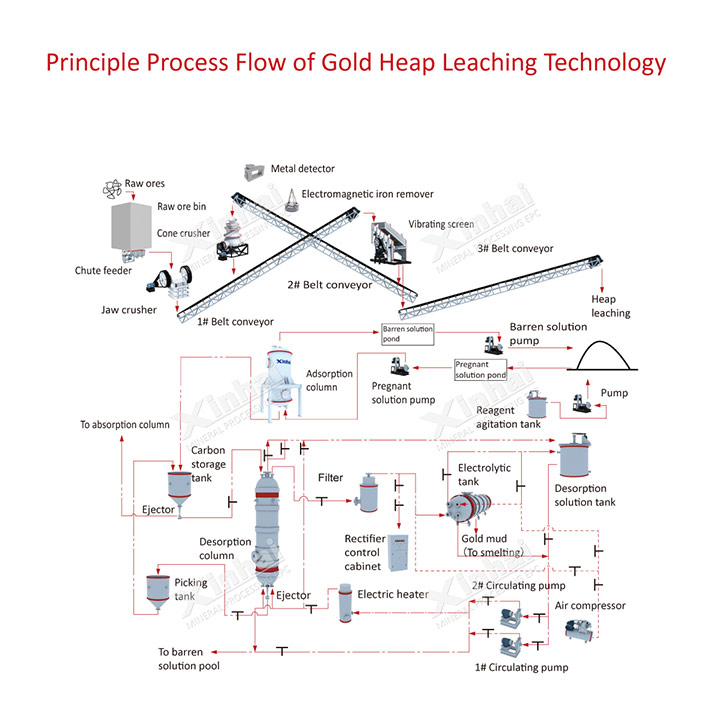

Heap leaching gold extraction process is not as widely used as gold flotation method. It is only suitable for gold mines with small ore bodies or of low grade that cannot be developed and utilized by conventional methods. In the separation of high-grade gold ore, in order to get a higher grade of gold concentrate, a single heap leaching process is not a good choice. And the concentrators will use combined processing method based on heap leaching method and CIL carbon leaching method.

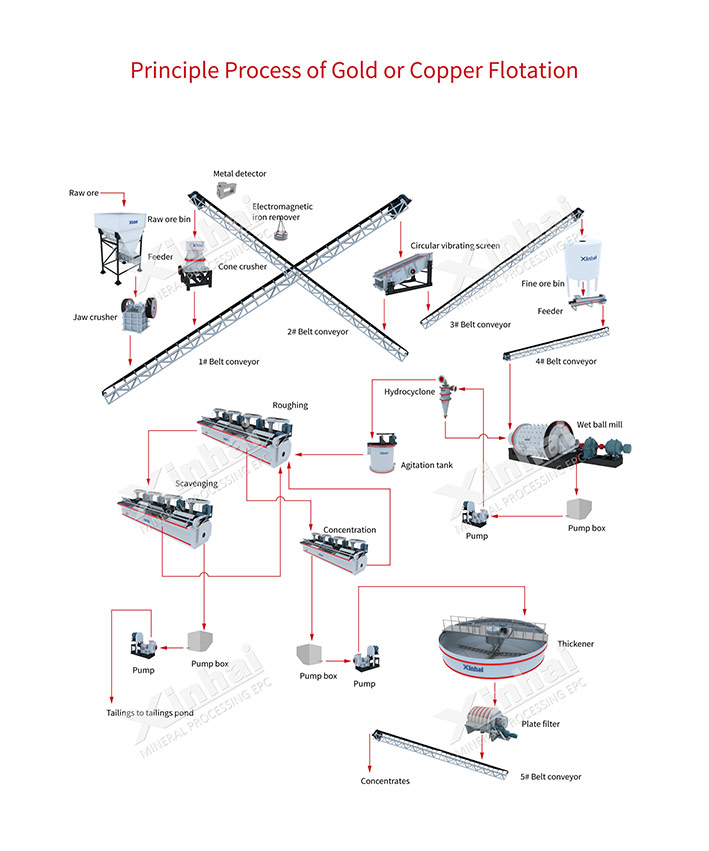

Since the application fields are different, of course, the separation process is also quite different. The gold flotation process generally adopts a one-stage grinding-flotation process. One-stage grinding and flotation process can be used for ores with uneven embedded particle size. In China, one-stage grinding-flotation process is generally adopted to achieve the enrichment of useful minerals. The conditions that affect the flotation results of gold ore include: grinding particle size, slurry concentration, dosage of flotation agent, aeration amount and flotation time, etc. Of course, you need to carry out gold ore beneficiation test to determine these specifications.

In terms of equipment selection, there is a little difference between gold ore flotation process and other conventional flotation process. The equipment needed in a flotation concentrator is as follows: jaw crusher, wet ball mill, classifier, flotation equipment and necessary de-watering equipment. The equipment used in heap leaching method for gold extraction is relatively special. In addition to the conventional crushing, grinding and classification equipment, leaching agitation tanks, desorption electrolysis systems or zinc powder replacement systems are also used.

The above introduces the differences between the gold mine heap leaching process and the gold mine flotation process from three aspects. We suggest that you do a beneficiation test to design the proper beneficiation process and related equipment. If you have any needs about beneficiation process design, beneficiation test, etc., welcome to cooperate with us Xinhai Mining Company. We will tailor a beneficiation plan for your mine to ensure a high recovery rate and improve the grade of concentrate!