Gravity separation is one of the commonly used methods for gold beneficiation. It uses different specific gravity of materials and different settling speeds in the medium to achieve the purpose of separation. Generally, in placer gold mines, gold mostly exists in the form of single natural gold, which has a large density difference with gangue.

There are many kinds of gravity separation methods, such as jig gravity separation, shaking table gravity separation, chute gravity separation, screw gravity separation, centrifugal gravity separation and wind gravity separation. The commonly used gravity separation methods for gold ore are jig separation, shaking table separation and chute separation.

The main jigging equipment for gold ore are jiggers. The jigging process is to mix mineral particles of different specific gravity, and stratify according to specific gravity in a vertically moving variable-speed medium flow. Minerals with small specific gravity are located in the upper layer, and minerals with large specific gravity is located in the lower layer. And the layered materials are discharged separately by the action of machinery and water flow.

Jigging separation is suitable for sorting coarse-grained gold mineral particles (raw mineral of any particle size except fine materials). The particle size of ore can be between 50mm to 0,074mm. when the gravity difference is bigger than 1.25 and the alluvial gold achieve monomer dissociation, the lower limit particle size can reach 0.04mm. Jigging separation has some merits including simple process operation, large equipment capacity and rather good application effect in roughing gold ore.

The main equipment for the gold ore shaking separation is the shaking table, which is a separation equipment in the horizontal medium flow. The transmission mechanism is used to drive the bed surface to do longitudinal reciprocating motion, and the rush flow and the bed surface differential motion, and the ore particles are reciprocating. During the movement, it undergoes the layering action perpendicular to the bed surface and the separation action parallel to the bed surface, so that materials of different particle sizes are discharged from different sections of the bed surface to realize separation.

Shaking table gold separation is suitable for processing and sorting minerals with fine particle size. According to the particle size of the ore, it can be divided into three types: coarse sand shaking table, fine sand shaking table and ore mud shaking table. The coarse sand shaking table is suitable for sorting materials with a particle size of 2.0 to 0.5mm; the fine sand table is suitable for processing the ore particles with the material size range of 0.5-0.074mm, and the ore mud table is suitable for processing the ore particles with the material size of 0.074-0.037mm.

The feeding gold ore particle size range of shaking table is generally between 3mm-0.019mm. the advantages of the gold shaking table separation lie in stable and reliable operation, clearly visible ore belt distribution, higher rich ore ratio and easy management. Besides, only one process can separate all the useful minerals.

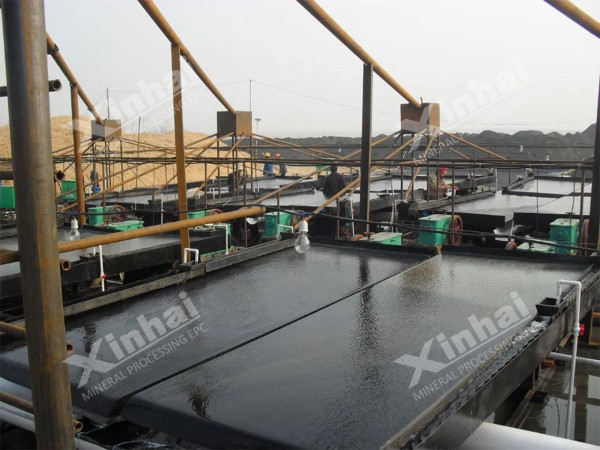

The main equipment for gold separation in chute is spiral chute, which is a kind of equipment that uses inclined water flow for sorting. The material uses the combined force of water flow, mineral gravity, and friction between ore particles and the bottom of the tank to make the ore particles settle in the tank according to specific gravity. In different areas in the interior, the ore particles with a small specific gravity are taken away by the water flow, leaving behind the ore particles with a large specific gravity, making the separation completed.

The spiral chute is suitable for processing fine-grained materials with low mud content. The proper material size range is 0.6-0.03mm. the feature of spiral chute is simple structure, large processing capacity and low comprehensive cost.

The above three methods of gravity separation are only used for gold ore (placer gold ore) with monomer dissociation. For vein gold minerals, the gravity separation process is rarely used alone. Generally, a combined process is formed with other processes, such as the gravity separation-flotation combined gold extraction process. The gravity separation is used to assist gold extraction. The gravity separation machines like jig, spiral chute and shaking table are used in the grinding and classification circuit to recover the easily dissociated coarse gold particles first, so as to create a better quality for the subsequent flotation and cyanidation processes. Using the combined process can effectively improve the gold ore index and the total gold recovery rate.