Gold ore beneficiation process mainly includes flotation process, cyanidation gold extraction process and so on. Gold ore flotation method often used to process gold-bearing sulfide minerals with high floatability. The gold flotation tailings still contain a small amount of useful components, which can be recovered to extract gold.

The flotation process can enrich gold into sulfide minerals to a large extent. Generally, tailings can be directly discarded. However, it is also necessary to analyze the composition of the tailings to determine how to deal with the gold tailings after flotation. Generally, the following steps should be followed:

1. Analyzing the composition in gold tailings

On the basis of accurate analysis of the composition of flotation tailings, try to achieve comprehensive recovery and utilization of useful elements. Usually, more advanced separation processes are used to re-separate the tailings to maximize the recovery of the flotation tailings and reduce the tailings emissions. The composition of gold tailings is determined through beneficiation tests, which mainly depends on the grade of gold in the tailings and whether it contains other substances with recovery value.

2. Determine the recovery process according to the gold grade in the tailings

After the experimental analysis of the composition of the gold tailings, the recovery process is determined according to the gold grade in the tailings. Generally speaking, the gold content in flotation tailings is not very high, usually around 0.3-0.5g/t. In view of the low grade and low value of gold in flotation tailings, the minerals with good flotation have been basically recovered in the previous flotation. The gold in tailings is poor in flotation, so flotation process is not a good choice.

In this situation, cyanidation leaching process can help obtained good indicator to some extent. However, the cost of cyanidation leaching process is very high because the process is relatively complicated and more equipment is used. Since the grade of gold flotation tailings is low, so cyanidation process is not economical. It cannot create good income, and may even lose money.

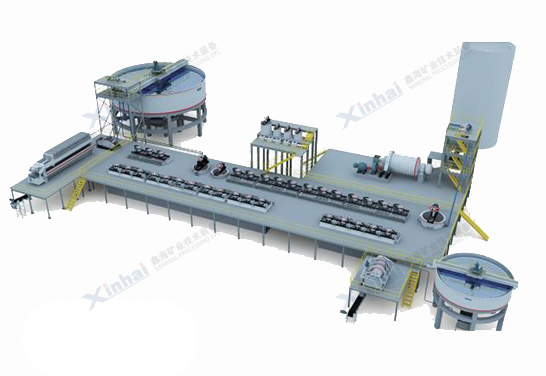

Therefore, the flotation and cyanidation leaching processes are discharged. Based on the principle of tail flicking enrichment and comprehensive recovery, we can choose the ideas of gravity separation and flotation for further enrichment and recover other useful components of tailings. That is to say, the gold tailings are first re-separated, and the use of gravity separation equipment such as spiral chute and shaking table is used to distinguish useful substances from wastes, and then the obtained concentrate is sent to flotation operation to obtain gold concentrate. Besides, the rest of the waste tailings are used to separate other useful minerals. This can not only save costs, but also improve the quality of gold, creating greater profit margins for customers.

3. Proper handling the discarded tailings

After recycling and re-separation, the waste materials should be properly handled. For some tailings containing silicon, aluminum, calcium and other oxides, they are used to produce cement clinker; tailings are used as the water sand filling or cemented filling materials of underground mined area; tailings are used to build road pavement materials, anti-skid materials and coastal land reclamation, etc.; the tailings are piled up and covered with soil for crops and trees planting; the tailings ponds are built to store the tailings, which is the most widely used tailings treatment method in most concentrators.

The above has introduced the recovery and re-separation methods of gold flotation tailings. In short, due to the low gold content of gold flotation tailings, you need to embrace the concept of low cost and high-income generation when starting the project. With the development of modern mining technology, the once abandoned tailings can create value today. Xinhai undertakes all-inclusive services for various metal and non-metal ore beneficiation and provide tailings dry discharge, re-separation and other processes. Welcome to inquire us and get your solutions.