Cyanidation gold extraction is currently an effective and high-efficiency method for gold ore beneficiation. The common cyanidation gold extraction methods include carbon in pulp process, carbon in leaching process, pool leaching and heap leaching process. This article briefly introduces four commonly used cyanidation leaching gold extraction processes.

The carbon in pulp extraction method (CIL), also known as the all-sliming cyanidation method, is a method of putting activated carbon into cyanide pulp, so that the dissolved gold is adsorbed on the activated carbon, and then the gold is extracted from the activated carbon.

CIL is suitable for gold mines with low sulfur and silver content and high mud content, and the recovery rate can reach more than 90%. CIL process has some merits over CIP process, including small footprint, low investment in infrastructure and leaching and desorption at the same time. The disadvantage that is difficult to overcome at present is that the consumption of gold-loaded carbon is high, and the amount of gold and silver lost with wear and tear of gold-loaded carbon is high. Among these four common cyanidation gold extraction processes, the investment of carbon in pulp extraction gold method is higher.

Carbon in leaching process (CIP) combines the process of adsorption and extraction on the basis of carbon in pulp method. Wash thickening is done before leaching. And carbon is added shortly after leaching, so that leaching and adsorption are carried out at the same time, and then the gold-loaded carbon is sent to desorption electrolysis system.

CIP is suitable for ore with a deep oxidation degree and does not contain copper, tin and carbon-containing substances. The gold processing method is simple in technology, convenient in operation, recyclable with activated carbon, and low in consumption. The disadvantage is that the leaching and adsorption processes are separated, so the floor space is large and the capital investment is high.

The pool leaching gold extraction method is suitable for low-grade gold and silver ores, tailings, and gold ores with low clay content. The beneficiation recovery rate can reach 50%~70%. The cost is slightly lower, which can improve low-grade gold mines with low economic benefits, simple operation and low personnel cost.

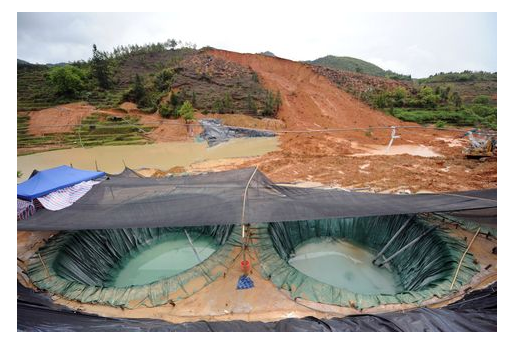

However, the initial construction cost of the pool leaching gold method is relatively high and the leaching time is relatively long, because it is necessary to build a leaching pool and a lean solution pool to ensure that the pool is not leaking, basically dry, and then the ore is placed in the leaching pool. Next, the leaching solution is prepared in the lean solution pool and then pumped to the leaching pool for leaching. After a period of time, the pregnant solution is released for replacement.

Heap leaching method for gold extraction is to put the ore on the impermeable material such as asphalt which has been preset for the water supply and drainage system, and then spray the leaching agent on the ore heap for leaching, so that the gold is leached into the pregnant liquid. It is discharged from the pipeline to the pregnant liquid pool for recycling.

Heap leaching method is suitable for low-grade gold and silver mines and tailings, and the recovery rate is 65~80%. It is of the lowest cost among the four beneficiation processes. The advantages are low cost, simple operation and simple infrastructure. The disadvantage lies in huge coverage area, long leaching time, and relatively strict requirement for ore.

Gold is a precious metal, so the selection of beneficiation process should be more careful. If the process is not properly selected, the recovery rate cannot be guaranteed, which will affect your economic benefits. Xinhai has rich experience in gold cyanidation extraction. If you have any need, please contact us.