As one of the gold extraction processes from gold mines, the CIP (Carbon in Pulp) method has always been favored by the advantages of high adsorption rate, high recovery rate and low investment cost. Compared with other gold extraction processes, the gold ore CIP carbon slurry method not only saves the expensive solid-liquid separation process, but also further optimizes each production link, so that the efficiency is significantly improved. According to the statistical analysis of project cases, Xinhai Gold Mine CIP carbon in pulp method can help customers save investment costs by 30%-50% and production costs by 8%-35%. The process flow of carbon in pulp extraction (CIP) is as follows:

The cyanidation pulp is screened to remove impurities such as coarse particles and sawdust before adsorption. And the activated carbon is ground before entering the adsorption tank to remove sharp corners and edges.

√ To avoid impurity adsorption of gold and activated carbon into the rich carbon, and prevent wood chips from clogging the carbon screen

√ To prevent activated carbon chips from entering the pulp and cause the loss of gold.

Add Xinhai's special coconut shell activated carbon into Xinhai's high-efficiency cyanidation leaching tank. The activated carbon adsorbs gold in the cyanide pulp to become gold-loaded carbon. After the adsorption is completed, the activated carbon and the pulp are separated by a carbon separator.

Compared with apricot core carbon, Xinhai coconut shell activated carbon has good adsorption capacity, which greatly improves the adsorption capacity and recovery rate of gold in associated metals, and its strong wear resistance reduces the loss of gold caused by the loss of gold-loaded carbon powder with the slurry.

Xinhai washing thickener adopts the method of continuous ore discharge, which reduces the multiple circulation of gold solution and achieves early recovery. In addition, it prolongs the thickening time of ore pulp and improves the washing effect.

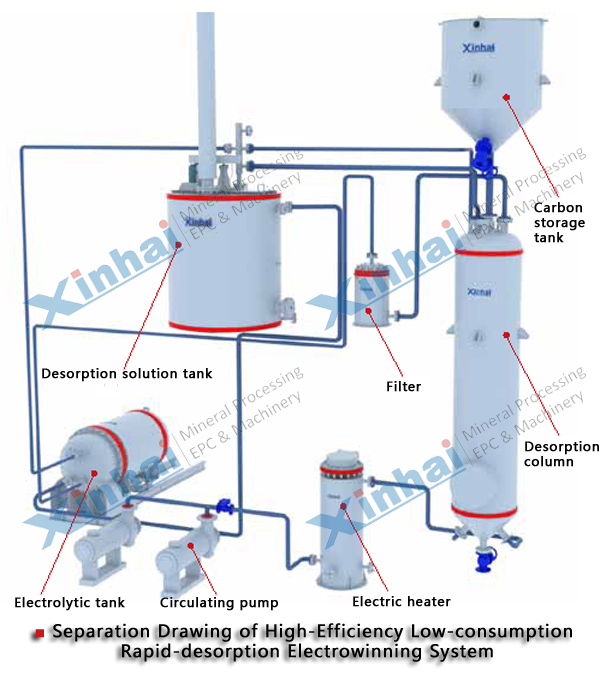

The gold-loaded carbon is rapidly desorbed and electrolyzed into gold mud and lean carbon in Xinhai's integrated high-efficiency, low-consumption and rapid desorption electrolysis system.

Xinhai high temperature and high pressure desorption method (150℃, 0.5Mpa), can desorb 99% of gold in only 2-6 hours

If the concentration of gold-silver cyanide complex ions in the pregnant liquid is high, high-purity solid gold can be obtained in one step through Xinhai’s high-efficiency, low-consumption and rapid desorption electrolysis system.

Gold mud can be directly smelted into gold ingots by high-frequency gold melting furnace after simple pickling, impurity removal and purification process.

Make sure that the gold mud and the agent are fully contacted and mixed in the pickling agitation tank, and the impurities in the gold mud or the acid-soluble inorganic substances in the solution are fully removed.

After regeneration, the lean carbon desorbed from gold can be reused when adding new activated carbon in proportion.

Xinhai coconut shell activated carbon is acid washed with dilute sulfuric acid (nitric acid) to remove carbonate and other accumulations after the desorption is completed, and then enters the regeneration furnace for thermal activation to restore the adsorption activity of the carbon. After the process, the iodine value of the carbon can be restored to more than 95%.