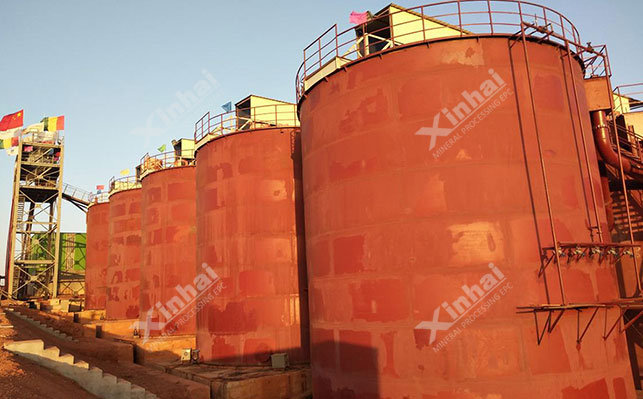

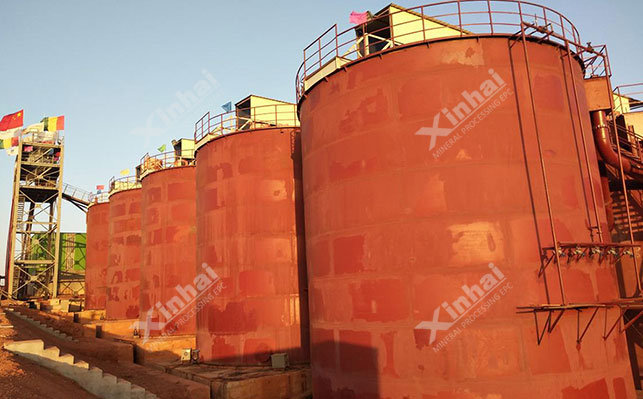

Cyanide leaching is one of the main methods for gold ore extraction. For the treatment of gold-bearing ores by cyanidation leaching, the recovery rate of cyanide leaching mainly depends on the effect of the leaching operation. In the case of maintaining the overall cost of the plant and improving the technical and economic benefits of the plant, how to adopt a reasonable leaching process and equipment, and how to choose a reasonable leaching condition, need to be determined by the gold leaching test. The test items for gold leaching test are roughly the same as the factors that affect gold leaching.

Gold monomer dissociation or bare gold surface is a necessary condition for cyanidation leaching. While grinding fineness is a key factor affecting the mineral monomer dissociation. In order to ensure that the cyanidation can obtain a higher index, it is necessary to study the effect of the particle size of the selected material on the cyanidation leaching, so as to determine the appropriate selected particle size (grinding fineness) according to the properties of the material.

The dissociation of minerals in ore is a key issue that needs to be solved in any beneficiation method. Only when the selected materials complete full or near full monomer separation can a high recovery rate be ensured, thus reducing the loss in the tailings as much as possible.

However, it should be noted that excessive over-grinding not only increases the grinding cost, but also increases the possibility of leachable impurities entering the leaching solution. In addition, it also makes the solid-liquid separation difficult, resulting in cyanide and Loss of soluble gold. Therefore, the grinding fineness needs to be further determined by leaching test.

However, it should be noted that over-grinding should not be caused by the excessive pursuit of small grinding particle size, which not only increases the grinding cost, but also increases the possibility of leachable impurities entering the leaching solution, and also makes the solid-liquid separation difficult, resulting in cyanide and Loss of molten gold. Therefore, the grinding fineness needs to be further determined by leaching test.

The leaching time is one of the important factors affecting gold leaching. During the leaching process of gold, the leaching rate of gold gradually increased with the prolongation of time, but the leaching rate decreased continuously due to the gradual increase in the thickness of the saturated solution layer on the gold surface, and the leaching rate gradually tended to a constant value.

In the cyanide leaching process, it is very important to determine the appropriate leaching time: if the leaching time is short, the gold minerals cannot be fully dissolved and leaching; if the leaching time is too long, larger equipment and site needs to be configured and the other impurities in the pulp also keeps dissolving, thus hindering the dissolution of gold. Therefore, it is necessary to determine the appropriate leaching time through the leaching test in order to improve the leaching efficiency and reduce the cost.

CN- is very unstable in solution, and easily becomes hydrogen cyanide gas to volatilize and cause chemical loss of sodium cyanide. Therefore, by adding lime to protect the alkali in the pulp, the pulp maintains a suitable alkalinity. The addition of lime can prevent the cyanide in the solution from generating HCN and volatilize, and at the same time, it can also cause some iron ions in the solution to form ferric hydroxide precipitation, reducing the consumption of cyanide.

In actual production, the amount of lime should be strictly controlled. Generally, the pH value is controlled in the range of 10~11. When the amount of lime is too much, due to its flocculation, the viscosity of the pulp increases, thereby increasing the resistance of solvent diffusion, correspondingly increasing the content of impurities in the solution, and increasing the degree of surface pollution of gold particles. At the same time, a calcium peroxide film may be formed on the surface of the gold particles, thereby hindering the effect of gold, sodium cyanide and oxygen, and reducing the leaching effect. When the amount of lime is insufficient, on the one hand, it will increase the consumption of sodium cyanide, which will affect the leaching index; on the other hand, the turbidity of the pregnant liquid is increased, causing the washing thickener to run off the groove. In order to determine the appropriate amount of lime addition, it is necessary to carry out the condition test of lime dosage.

The slurry concentration will directly affect the leaching speed and leaching rate of gold. The higher the concentration is, the higher the viscosity of the pulp and the poorer the fluidity, the lower the gold leaching speed of gold and gold leaching rates. When the concentration of the leaching pulp is low and the fluidity of the pulp is good, the leaching rate of gold will be higher. But the dosage of the chemical will also increase. Meanwhile, the equipment volume and investment cost will also increase relatively. Therefore, a suitable leaching slurry concentration is required to balance the gold leaching rate and production cost.

In the cyanidation process, the amount of cyanide agent is proportional to the gold leaching rate within a certain range. But when the amount of cyanide agent is too high, the cost increases, but the leaching rate of gold does not change much. At the same time, the addition method of the cyanide agent also has a certain influence on the leaching rate and leaching speed of gold.

Therefore, on the basis of the grinding fineness test, in order to further reduce the dosage of cyanide agent and the cost of production chemicals, and determine the addition method of cyanide agent, it is necessary to carry out the test of the dosage and addition method of cyanide agent.

The varying soluble degrees of associated minerals in cyanide solution will adversely affect gold leaching result. So this type of gold leaching requires pretreatment. The oxidative pretreatment of gold ore by adding oxidant can effectively improve the recovery rate of gold cyanide leaching in gold ore.

Gold ore leaching needs to carry out the pretreatment agent selection test, and the pretreatment agents are mostly calcium peroxide, sodium hypochlorite, sodium peroxide, hydrogen peroxide, citric acid, lead nitrate, etc. Usually, the leaching effect after pretreatment will be compared with that without pretreatment under normal circumstances. The purpose is to determine if a pre-processing job is required.

The above is the specific content included in the gold leaching test. It is recommended to entrust a manufacturer with concentrator research qualifications to conduct a beneficiation test before designing a beneficiation plant. According to the different properties of the ore, you can better clarify the process parameters of the leaching process to obtain a higher return on investment.