Cyanidation leaching method can be used for oxidized gold ore to complete quick gold extraction. This method needs to go through four steps:

(1) carrying out ammonia cyanide leaching of copper-containing oxidized gold ore to obtain pulp;

(2) adding hypochlorite, stirring to remove copper to get copper removal slurry;

(3) carrying out countercurrent washing of the de-copper pulp to obtain the pregnant liquid for washing;

(4) Using activated carbon to adsorb and extract gold from the washing liquid.

The use of hypochlorite to remove copper from cyanamide leaching pulp can effectively control the copper-gold ratio in the pregnant liquid. And it is not easy to produce high-copper carbon, which reduces the cost of subsequent smelting. In addition, the process is short and the cost of reagents is low.

In the first step, ammonium salt and sodium cyanide are added to the copper-containing oxidized gold ore in three times, wherein the ratio of ammonia to cyanide in the initial stage is 3.0-4.0:1, the concentration of ore pulp is 10-50%, and the pH is 11-12; The ratio of ammonia to cyanide in the second stage is 1.0-2.0:1, the concentration of pulp is 10-50%, and the pH is 11-12; the ratio of ammonia to cyanide in the third stage is 0.5-1.0:1, the concentration of pulp is 10-50%, and the pH is 11-12;

In the second step, the leaching pulp is washed with countercurrent in three stages. The concentration of the undercurrent in the first stage is 50-55%, the washing water-ore ratio is 3-5:1, the time is 8 to 10 hours, and the temperature is 10 to 40 degrees Celsius; the second stage of washing The underflow concentration is 50-55%, the washing water-mineral ratio is 3-5:1, the time is 8-10 hours, and the temperature is 10-40 degrees Celsius; the third-stage washing underflow concentration is 45-50%, and the washing water-mineral ratio is 3-5: 1. The time is 8 to 10 hours, and the temperature is 10 to 40 degrees Celsius; after three stages of washing, the pregnant liquid is washed for later use;

The third step is to wash the pregnant liquid carbon with a density of 10-15 g/L and conduct adsorption for 24-36 hours.

Above we have introduced the gold extraction method and gold extraction steps of oxidized gold ore, so what are the gold oxide beneficiation equipment?

1. Leaching agitation tank

The leaching agitation tank is a cyanidation leaching and stirring equipment. The double-impeller leaching and agitation tank is suitable for the leaching and adsorption of gold ore with small specific gravity, low viscosity, slow settling speed, ore particle size of -200 mesh accounting for more than 90%, and pulp concentration of less than 45%. and other mixed operations.

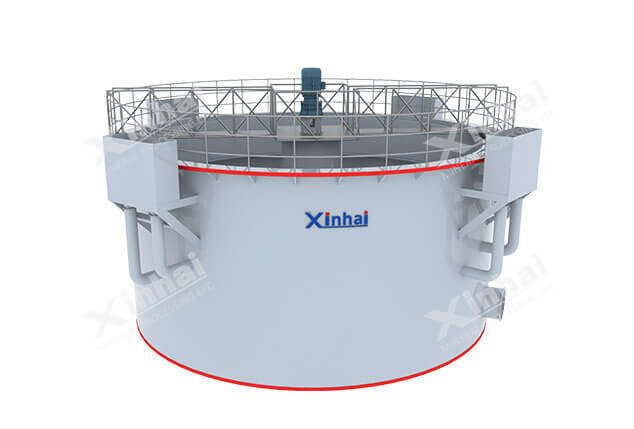

2. Washing thickener

The washing and thickening machine is a special equipment for the solid-liquid separation and washing operation of the pulp after cyanidation leaching, and can be used for the dehydration of uranium mines in hydrometallurgy, light industry and chemical industry. Washing thickener has some merits including countercurrent washing, large volume and high washing efficiency.

3. Desorption electrolysis system

The high-efficiency and low-consumption rapid desorption electrolysis system consists of a desorption column and an electrowinning cell. The desorption electrolysis system is a set of gold beneficiation equipment that obtains gold mud from gold-loaded carbon through desorption and electrowinning under high temperature and high-pressure conditions. It is often used to extract solid gold from gold-loaded carbon in cyanidation alchemy process.