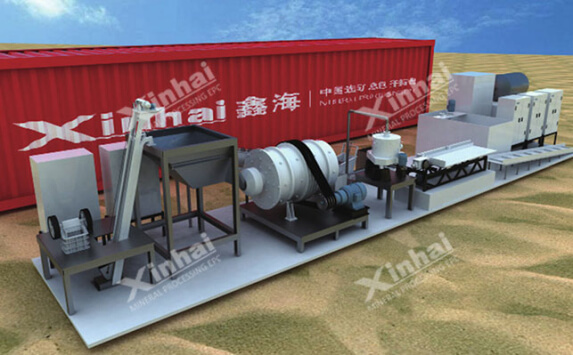

The mobile gold processing plant developed by Xinhai is composed of a variety of mobile gold processing equipment, mainly aiming at the characteristics of some mines, such as high-grade gold ore, coarse embedded particle size, small and scattered mining scale, etc.

This system adopts the design concept of modularization and integration, mainly used for the recovery of gold minerals in small-scale mines with scattered raw material sources. It is convenient for adopting a nomadic business model to process ores for retail mining customers. According to the different processes, it can be divided into mobile gravity separation plant, mobile cyanidation plant, mobile flotation plant, mobile gravity separation + cyanide plant. According to the level of equipment matching, it can be divided into basic type and flagship type. According to different raw materials, it can be divided into raw ore processing mobile plant and tailings processing mobile plant.

After being mined, the ore is manually fed into the jaw crusher for crushing. The crushed products are transported to the steel powder ore bin by the skip hoist, and the materials in the powder ore bin are evenly fed into the ball mill for grinding. The grinding products are fed into the jig, and the coarse concentrate of the jig is fed into the shaking table for selection to obtain the gold concentrate 1 for gravity separation. The tailings of the jig are returned to the spiral classifier for classification, and the classifier sand returns come to the ball mill to form a closed-circuit grinding process. The overflow of the classifier is pumped into the centrifugal concentrator for separation, and the concentrate is regularly taken out of the centrifugal concentrator and selected with a shaking table to obtain gravity concentrate 2.

After mined from the mine, the ore is manually fed into the jaw crusher for crushing. The crushed products are transported to the steel powder ore bin by the skip hoist, and the materials in the powder ore bin are evenly fed into the ball mill for grinding. The grinding products are fed into the spiral classifier for classification, and the classifier sand returns come to the ball mill to form closed-circuit grinding. The overflow of the classifier is pumped into the high-efficiency thickening box for concentration, and the concentrated pulp is pumped into the leaching tank unit for cyanidation leaching. Activated carbon and cyanide agents are manually added to the leaching tank; the carbon is extracted by an air lifter, and the saturated gold-loaded carbon is washed by a fixed mesh screen and sent to desorption electrolysis and smelting.

After being mined, the ore is manually fed into the jaw crusher for crushing. The crushed products are transported to the steel powder ore bin by the skip hoist, and the materials in the powder ore bin are evenly fed into the ball mill for grinding. The grinding products are fed into the spiral classifier for classification, and the classifier returns to the ball mill to form closed-circuit grinding. The overflow of the classifier is pumped into the high-efficiency agitation tank for dosing and stirring, and then enters the flotation system. The flotation system adopts the one roughing-two sweeping-two refining process. The middling is returned in sequence at one time, and the concentrate is pumped into the filter press by the hose pump for filtration to obtain the final gold concentrate.

It is worth mentioning that, on the basis of the above three mobile processing plants, the basic mobile gravity separation system MRGB-5, the basic mobile cyanidation system MRCB-5, and the basic mobile flotation system MRFB-5, Xinhai can make the modularized and customized manufacturing according to the needs of customers. The crushing module is replaced by the tailings pulping module, so there are another 3 models, namely, the basic tailings gravity separation system MTGB-5, the basic tailings cyanidation system MTCB-5 and the basic tailings flotation system MTFB-5.

1. Excellent technical performance

According to the mineralogical characteristics of the ore process, Xinhai has specially designed the process flow to ensure the 24-hour continuous production of the mobile processing plant with excellent equipment performance, while ensuring high recovery rate.

2. Easy to transport and assemble

For the basic mobile dressing plant, the entire system is assembled on a set of steel overall frame, without the complex equipment foundation of traditional dressing plants, and simple wheels can be installed, which is convenient for loading, unloading and transportation, so as to achieve "drop-in production, load-on-trucks transfer"!

As a mobile concentrator, the obvious advantage is that each concentrator has been processed, assembled and debugged at the factory, fully packed in containers and shipped to the mining area. There is no need for professional installers, and on-site workers can start mineral processing by simply connecting water and electricity.

3. Safe and simple operation and maintenance

The whole system is simple solution. While retaining the basic functions of the plant, redundant auxiliary equipment is removed, and automatic control is realized as much as possible. The operation is simple, safe and reliable, and the indicators are stable.

4. Local after-sales service

Xinhai has set up after-sales service centers and spare parts warehouses in many countries and regions. Once the customer encounters problems in the operation of the plant operation, we can respond quickly and send technicians to help solve them in time to avoid delays in production.

5.Various equipment configuration options

At present, Xinhai has developed a 5t scale mobile gold processing plant including gravity separation plant, cyanidation plant and flotation plant. According to the characteristics of the customer's ore, Xinhai customizes and combines the technological process and equipment to ensure the equipment performance and recovery rate.

According to the level of equipment configuration, Xinhai can provide basic type and flagship type mobile dressing systems.

◆ Basic type: high cost performance under the premise of meeting the basic operation requirements of the system.

◆ Flagship type: Various optional equipment can be added according to the needs of customers and dressing plants, such as: full-size sports base, retractable sunshade, one-key start-stop console, independent tailings dry discharge module, independent smelting module, etc. A variety of optional equipment can be invested at one time, which is more convenient and practical.