Alluvial gold mining is a method of extracting gold from riverbeds, streams, and other sedimentary environments where gold particles have been deposited by water movement. This method differs from hard rock mining, which involves extracting gold from primary deposits embedded in solid rock. Efficient processing of alluvial gold requires the use of various specialized equipment to maximize gold recovery and minimize environmental impact. This article explores the essential mineral processing equipment used in alluvial gold mining, detailing their functions, benefits, and operational considerations.

Alluvial gold mining has been practiced for centuries, dating back to ancient civilizations that panned riverbeds for gold nuggets and dust. Modern alluvial gold mining leverages advanced technology to process larger volumes of sediment and extract gold more efficiently. The primary objective is to separate gold particles from sand, gravel, and other materials using gravity separation methods. This process is typically less labor-intensive than hard rock mining and does not require the use of toxic chemicals.

(1)Trommel

A trommel is a rotating cylindrical screen used to separate materials by size. It is commonly used in alluvial gold mining to screen out large rocks and debris.

Function: Sediment is fed into the trommel, where it is rotated and screened. Smaller particles pass through the screen for further processing, while larger debris is removed.

Advantages: Automates the screening process, allowing for the processing of large volumes of material and increasing efficiency.

Limitations: Requires significant setup and maintenance and is generally used in more permanent mining operations.

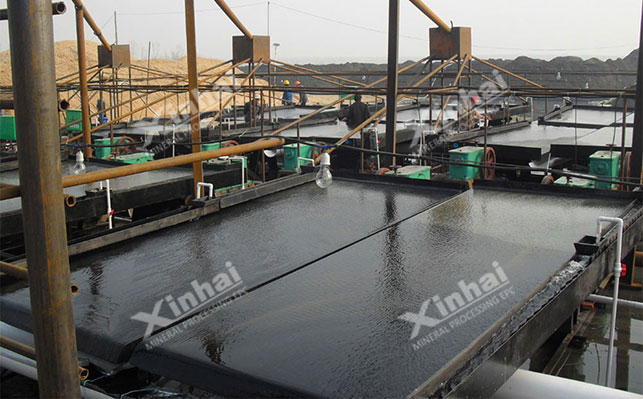

(2)Shaker Table

A shaker table, or gold shaking table, uses vibration and gravity to separate gold particles from other materials.

Function: Material is fed onto the table, which vibrates, causing heavier gold particles to move to one side while lighter particles are washed away.

Advantages: High recovery rate for fine gold particles, allowing precise separation and concentration of gold.

Limitations: Requires a stable, level setup and continuous feeding of material. More suitable for final processing stages.

(3)Centrifugal Concentrator

A centrifugal concentrator uses centrifugal force to separate gold particles from other materials.

Function: Material is fed into the concentrator, which spins at high speeds. The centrifugal force causes heavier gold particles to be separated and collected.

Advantages: Highly efficient for fine gold recovery and capable of processing large volumes of material quickly.

Limitations: Requires continuous feeding and monitoring, with higher initial costs and maintenance requirements.

(4)Jig

A jig uses pulsating water flow to separate gold particles from other materials based on their density.

Function: Material is fed into the jig, where it is subjected to pulsating water flow. Heavier gold particles settle to the bottom, while lighter particles are carried away.

Advantages: Effective for recovering coarse gold particles and capable of processing large volumes of material.

Limitations: Requires precise setup and operation and is less effective for very fine gold particles.

While alluvial gold mining is generally less invasive than other forms of mining, it still has significant environmental impacts if not managed properly. The use of equipment such as dredges and highbankers can disturb riverbeds and aquatic ecosystems. Adhering to best practices and regulatory guidelines is crucial to minimizing environmental damage.

3.1 Best Practices

Erosion Control: Implement measures to prevent soil erosion and sediment runoff into water bodies, such as using silt fences and planting vegetation.

Rehabilitation: Restore mined areas by replanting vegetation and stabilizing disturbed soil to promote ecosystem recovery.

Water Management: Ensure proper management of water resources to avoid contamination and depletion, including using sediment control systems and recycling water.

3.2 Regulatory Compliance

Compliance with local, national, and international regulations is essential for responsible alluvial gold mining. Regulations may include obtaining permits for water use, adhering to restrictions on dredging activities, and fulfilling requirements for land rehabilitation.

Alluvial gold mining relies on a variety of specialized equipment to efficiently separate gold from natural deposits. From the basic gold pan to advanced centrifugal concentrators, each piece of equipment plays a crucial role in the mining process. Understanding the functions, advantages, and limitations of each type of equipment allows miners to select the best tools for their operations, ensuring more effective and sustainable gold extraction. Additionally, adhering to best practices and regulatory guidelines is essential for minimizing environmental impact and promoting responsible resource management in alluvial gold mining. By leveraging the right equipment and techniques, miners can optimize gold recovery while safeguarding the environment for future generations.