With the continuous large-scale mining of gold mines, easily leachable gold resources are becoming increasingly depleted. In order to obtain more valuable gold resources, miners have shifted their focus to the direction of difficult to handle gold resources. However, technically difficult to handle gold ore is difficult to beneficiate, and it needs to be pre treated first. Next, Xinhai will explain why gold ore needs to be pretreated and the methods of gold ore pretreatment.

Generally, gold ore that requires pre-treatment is difficult to select. For example, gold ore contains impurities such as arsenic and carbon, and the leaching stirring rate is less than 80%. So why do we need to perform preprocessing? The purpose is to expose these difficult to handle encapsulated gold particles for subsequent leaching operations.

1. Through pre-treatment, sulfides that encapsulate gold minerals can be oxidized, forming porous minerals that give cyanide solutions the opportunity to come into contact with gold particles;

2. Impurities such as arsenic, antimony, and organic carbon that hinder cyanide leaching can be removed from gold;

3. Pre treatment can turn difficult to leach telluride gold into easily leachable gold.

The common pre-treatment methods for gold ore in mineral processing mainly include: hot pressure oxidation process, roasting oxidation process, and biological oxidation process.

1. Gold ore hot pressure oxidation method

It is the process of using air (or oxygen rich) for hot pressure gasification in a high-pressure reactor. By heating and oxygenating, the crystals of sulfide ore and some gangue minerals are destroyed, exposing the encapsulated gold, and then completing oxidation leaching of gold to obtain gold concentrate. The main feature of this method is that the oxidation products of pyrite and arsenopyrite are soluble, and the gold recovery rate is high; It can directly process the raw ore, making it more effective for recovering gold mines that are difficult to float; No smoke pollution issues.

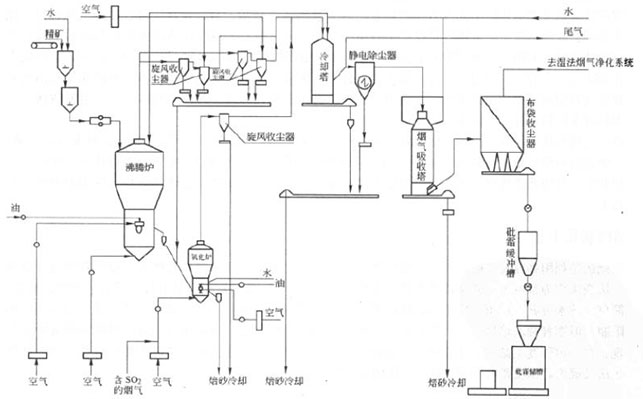

2. Gold ore roasting and oxidation method

Inflating at high temperatures decomposes the sulfide ore that encapsulates gold into porous oxides, exposing the gold and obtaining qualified gold through leaching. This method has a fast processing speed and strong adaptability, especially for ores containing organic carbon, and can comprehensively recover associated elements such as arsenic and sulfur.

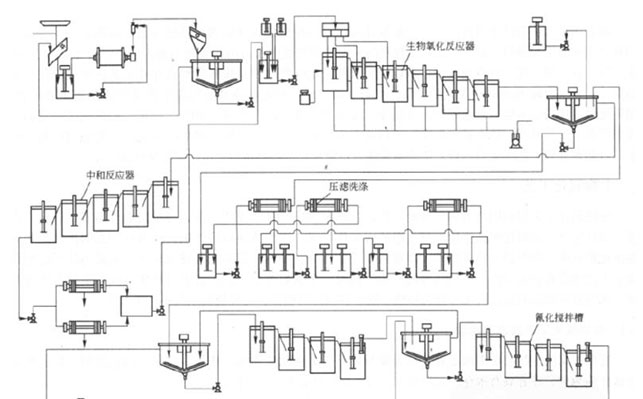

3. Biological oxidation method of gold ore

The main method is to use microorganisms in nature to select sulfur and iron loving mineral free strains, and through adaptive cultivation and domestication, utilize the direct or indirect effects of metabolic products of these microorganisms in suitable environments to directly or indirectly oxidize and decompose the sulfide ore matrix, destroy harmful components such as pyrite and arsenopyrite that encapsulate gold, fully expose gold, and create favorable conditions for subsequent cyanide gold extraction processes, achieving efficient recovery. At the same time, during the oxidation process, harmful elements such as arsenic and sulfur that cause pollution to the environment in the ore decompose into relatively stable harmless salt substances, which are neutralized and precipitated before being stored, without causing pollution to the environment and atmosphere.

The above is an introduction to why gold mines undergo pre-treatment and several common methods of gold mine pre-treatment. In order to obtain more gold resources, it is not only difficult to treat gold, but also investment recovery can be carried out when the gold content in old tailings is above 3%. Xinhai Mining Equipment can conduct beneficiation experiments for various gold mines, customize gold ore beneficiation process plans, gold ore beneficiation construction plans, and complete sets of gold ore beneficiation equipment. If you have any needs, please feel free to consult.