The beneficiation of gold ore is a complex and delicate process. Among numerous beneficiation equipment, the carbon screen has become an indispensable part of gold ore pretreatment due to its unique function and efficient performance. This article will provide a detailed introduction to the working principle, equipment structure, and operation process of the carbon screen. And introduce its application in gold ore beneficiation.

Carbon screen is mainly used in the pretreatment stage of gold ores.Especially when processing carbonaceous gold ores. The presence of carbonaceous substances may have adverse effects on the subsequent flotation process, reducing the recovery rate and purity of gold. Therefore, separating carbonaceous material from ore before flotation is a key step in improving mineral processing efficiency.

The working principle of the carbon screen is based on the screening effect, and the particle size of the material passing through is controlled by the aperture size of the screen mesh. The equipment is equipped with multiple layers of screens inside, and carbonaceous materials and ores are effectively separated during the screening process due to differences in particle size and density. This process is not only simple and efficient, but also easy to operate and maintain.

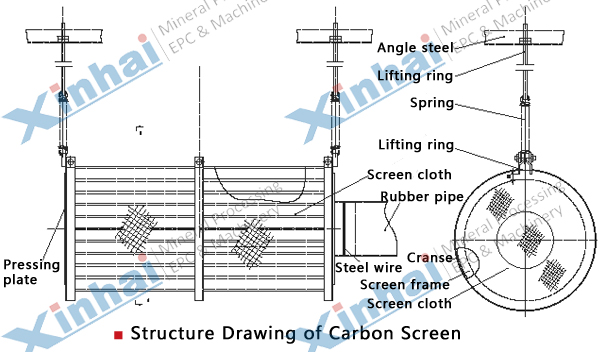

The structure design of the carbon screen is compact and efficient, mainly including the following parts:

1. Screening box: This is the main part of the carbon screen, which is equipped with multiple layers of mesh inside. The design of the screening box ensures the uniform distribution and efficient separation of materials during the screening process.

2. Sieve: It is usually made of stainless steel or other wear-resistant materials, and the pore size can be adjusted as needed to adapt to materials of different particle sizes.

3. Support frame: used to support the screening box and ensure the stability of the screening process. The design of the support frame needs to consider the durability of the equipment and the convenience of maintenance.

4. Drive device: Some carbon screens may be equipped with vibration or rotation drive devices to improve screening efficiency. The selection of the driving device should be determined based on the characteristics of the material and screening requirements.

The operation process of the carbon screen is relatively simple, mainly including the following steps:

1. Feeding: Evenly feed the carbonaceous gold ore into the charcoal sieve. The uniformity of the feeding is the key to ensuring the screening effect.

2. Screening: The ore is classified through the aperture of the sieve in the screening box, and the carbonaceous material and ore are separated. During the screening process, the flowability of the material and the aperture of the sieve are important factors affecting the separation efficiency.

3. Discharge: The sieved material (usually carbonaceous material) and undersized material (gold ore) are discharged separately and enter the subsequent processing flow. The timeliness and accuracy of discharge have a direct impact on the efficiency of the entire beneficiation process.

Carbon screening has multiple advantages in the process of gold ore beneficiation:

1. Improve beneficiation efficiency: By effectively removing carbonaceous substances and reducing interference with subsequent flotation processes, the recovery rate of gold can be increased.

2. Improve product quality: Reduce the pollution of carbonaceous substances on the final gold product, improve the purity of gold, and enhance the market competitiveness of the product.

3. Easy to operate: The device has a simple structure and is easy to operate and maintain, reducing the skill requirements and maintenance costs for operators.

4. Strong adaptability: Suitable for gold ores of different particle sizes and properties, with good universality and flexibility.

When using a carbon screen, the following aspects should be noted:

1. Sieve selection: Select the appropriate sieve aperture based on the particle size of the ore and carbonaceous material to ensure the screening effect.

2. Regular maintenance: Regularly check the wear of the screen mesh, replace damaged screens in a timely manner, and ensure the stability of the screening effect.

3. Uniform feeding: Uneven feeding can affect the screening effect. It should be ensured that the feeding is uniform and continuous to avoid material blockage and screen damage.

Carbon screening not only plays an important role in the pretreatment of gold ores, but can also be applied to other occasions that require material grading, such as coal, building materials, chemical industries, etc. Its efficient screening ability and stable performance have made it widely used in multiple fields.

As an auxiliary equipment,the carbon screen plays a crucial role in the beneficiation process of gold ore. By effectively separating carbonaceous substances, not only has the beneficiation efficiency of gold ore been improved, but the purity and quality of the final product have also been enhanced. With the increasing scarcity of gold ore resources and the development of mineral processing technology, the application prospects of carbon screen will be even broader.

Through the introduction of this article, we can see the importance of carbon screening in gold ore beneficiation. It is not only an efficient screening equipment, but also an indispensable invisible assistant in the gold ore beneficiation process.