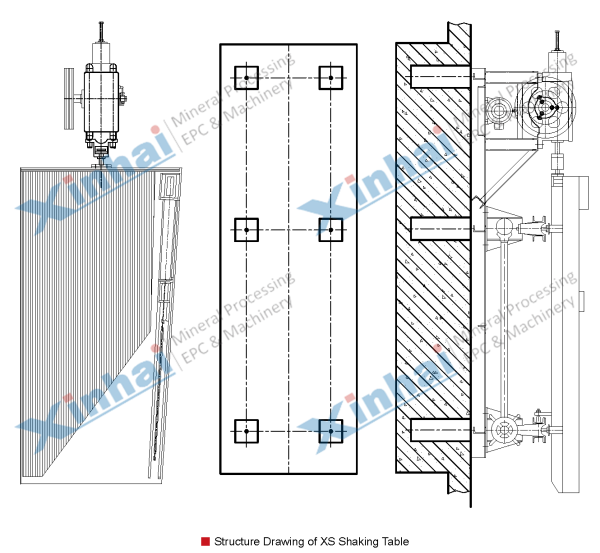

Shaking table is a widely used mineral processing equipment. Its basic structure is divided into three main parts: bed surface, bed head and frame.

The bed surface can be made of wood, glass fiber reinforced plastic, metal (such as aluminum, cast iron) and other materials. The common shapes are rectangle, trapezoid and rhombus. Many parallel bed strips (also known as Laifu strips) or grooves are nailed on the bed surface along the longitudinal direction. The bed strips are lowered from the driving end to the opposite side and are pinched out on a diagonal line. The bed surface is supported by the frame or lifted by the frame. The bed surface of the shaking table is inclined. It is inclined from the ore feeding end to the opposite side at 1.5 ° - 5 ° in the transverse direction. Thus, the water flow fed by the ore feeding tank and the flushing tank forms a thin inclined water flow on the bed surface. There is a feeding trough on the right upper part of the bed surface, with a length of about 1 / 4-1 / 3 of the total length of the bed surface; There are many small holes on one side of the ore feeding trough to make the slurry evenly distributed on the bed surface. The flushing tank is connected to the ore feeding tank, which accounts for 2 / 3 ~ 3 / 4 of the total length of the bed surface. Many small holes are also opened at the side of the water feeding tank, so that the flushing water can be fed evenly along the longitudinal direction of the bed surface. Many valves are also installed in the tank to adjust the distribution of water along the length of the bed.

Driven by the motor, the bed surface is connected through the pull rod to make the bed surface move asymmetrically in the longitudinal direction. When the bed surface moves forward, the speed changes from slow to fast and then stops quickly; When retreating, the speed rapidly increases from zero to the maximum, and then slowly decreases to zero. The bed surface produces longitudinal differential movement, so that the ore particles on the bed surface can be transported in one direction. Transport to the concentrate end is called forward transport, and vice versa.

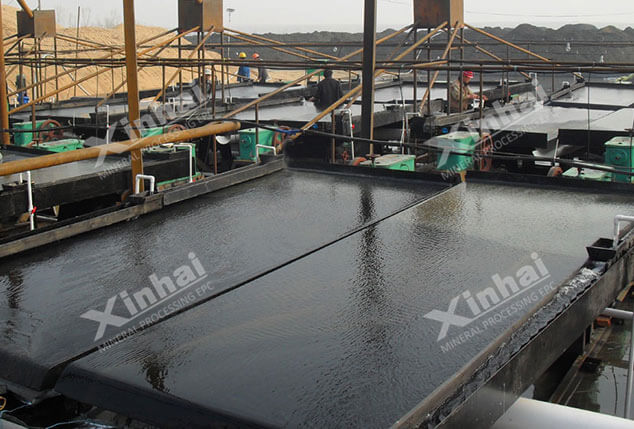

The bed surface is supported by sitting type and hanging type. The sitting type is that the bed surface is directly connected with the support, and a slope adjusting device is set on the support to adjust the cross slope of the bed surface. The hanging type is to hang the bed surface on a rack with wire rope, and the bed surface is suspended in the air. Adjust the slope by adjusting the tension of the steel wire rope. During the sorting of the shaking table, the flushing water fed by the water supply tank will be spread on the transversely inclined bed surface and form a uniform thin layer of water flow on the inclined surface.

When the material (generally hydraulic graded product, slurry with concentration of 25% ~ 30%) flows from the ore feeding trough to the bed surface, the ore particles are loosened and layered in the bed strip groove by the water washing and bed surface vibration. The light mineral particles in the upper layer are subject to large impact, and most of them move downward along the transverse slope of the bed surface, and the discharge is called tailings.

This side of the corresponding bed surface is called tailings side. While the heavy mineral particles at the bottom of the bed move longitudinally by the differential movement of the bed surface, and are discharged from the opposite side of the transmission end, which is called concentrate, and the corresponding bed surface position is called concentrate end. The ore particles with different density and particle size are subject to different transverse and longitudinal effects on the bed surface, and the final movement direction is different. However, they are fan-shaped on the bed surface, and can receive a variety of products with different quality.

The advantages of the shaking table are high separation accuracy, large enrichment ratio, and obvious and intuitive zoning of materials on the bed surface, which is convenient for timely adjustment of parameters. Its disadvantages are large floor area and low processing capacity. Therefore, the coarse concentrate of placer gold is generally cleaned by shaking table. For vein gold ore, the shaking table is generally used as the cleaning equipment or roughing equipment in the single gold recovery process.