When using the carbon-in-leach method or the carbon-in-pulp method to extract gold, the adsorption characteristics of activated carbon are used to inhale the gold in the slurry into the pores of the activated carbon. At this time, the activated carbon becomes the gold-loaded carbon, and the gold in the gold-loaded carbon is desorbed. The process is called desorption electrolysis. Here is an introduction to the high temperature and high pressure desorption electrolysis process.

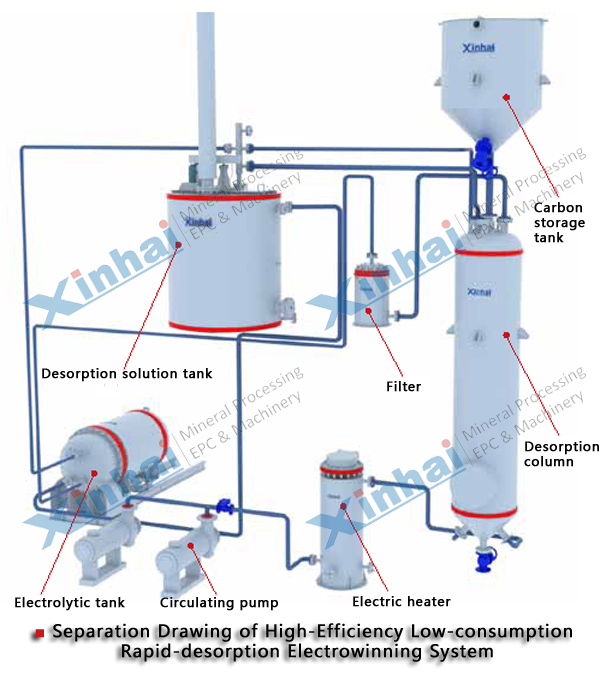

1. After pretreatment, the carbon loaded with gold enters the linear vibrating screen, and the carbon powder flows away with the liquid. The smaller particle size that is not suitable for the desorption process is collected under the screen, and the material on the screen enters the carbon storage tank. The carbon slurry entering the carbon storage tank cannot contain mud and impurities. The position of the carbon storage tank should be at the upper end of the desorption column. After the connection valve is opened, it is added to the desorption column.

2. Water and sodium hydroxide is added to the analytical solution tank. The ratio needs to be determined according to the scale of the gold-loaded carbon to be processed. The height of the liquid is about 30-40 cm from the top of the tank, and the liquid flows into the circulating pump (2 circulating pumps should be prepared, one of which is for standby), which is pumped into the heater (two heaters are connected in series) to heat the liquid to 150°C.

3. After the liquid is heated, it reaches the bottom of the desorption column, and mixes with the gold-loaded carbon, flows up through the carbon layer, and then overflows from the overflow pipe. The overflowing liquid enters the filter to filter out the mud and impurities inside. When the liquid in the electrolytic tank is full, the valve of the analytical liquid tank will automatically close, and no more liquid will be injected. The overflow in the electrolytic tank enters the circulating pump again, and the whole process takes 6-8 hours.

Note: In this process, in order to make the whole system enter the high temperature and high pressure environment as soon as possible, the air compressor will be used to pressurize after the cycle is normal. The purpose of pressurization is to increase the boiling point, thus increasing the pressure throughout the system.

4. When the temperature drops to about 110℃, the electrolytic cell starts to energize and restores the gold mud. After this process, the carbon can be released. At this time, the carbon is no longer gold-loaded carbon, and will return to the adsorption process to continue working, and the gold sludge is deposited in the electrolytic cell.

5. The whole system stops running, the pressure is removed, and the temperature drops. At this time, the electrolytic cell can be opened, the cathode inside can be taken out, washed with clean water, collected the washed things, treated with acid, removed impurities, purified, drying and smelting. After all these processes, the entire desorption electrolysis process of the gold-loaded carbon is completed.

The above is the introduction of desorption and electrolysis process of gold-loaded carbon. The desorption and electrolysis equipment independently developed by Xinhai has a series of advantages, including high desorption rate (6-8 hours), good desorption effect (resolution rate above 98%), and low power consumption (1/2-1/4 of conventional equipment), less environmental pollution (no cyanide).