[Introduction]: A periodic and reciprocating feeding machine for large bulk materials.

[Capacity]: 10~90t/h

[Improvement]: According to user requirements, the motor can be changed to the speed adjustment motor to adjust the feeding volume.

Simple structure, even feeding, good continues performance;

Change and control flow and feeding volume at any time;

Stable transmission, high efficiency;

Compact structure, reasonable design;

Excellent quality, wide application.

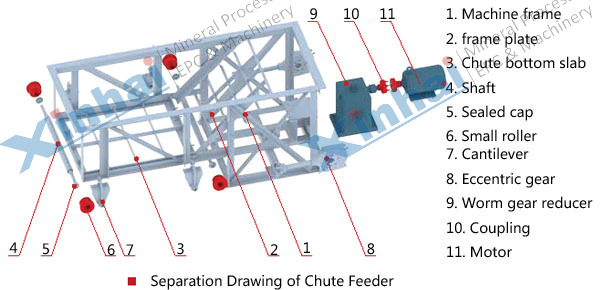

The machine is usually installed underneath the discharging opening of the ore bin. Minerals fall on the bushing. The bushing is located at the chute bottom, configured on the idler wheel, and via an eccentric device connected with a reducer which is linked to an electric motor by a coupler. When it works, the electric motor drives a reducer via a coupler; eccentric disk and drain cap which is situated between the chute frame bottom and roller begins to do reciprocal and linear motion to uniformly feed minerals.

| Model | Outlet Dimension (W X H) (mm) | Max. Feed Size (mm) | Feed Capacity (t/h) | Motor Model | Motor Power (kW) | Weight (kg) |

| CG300X300 | 300X300 | 50 | 10~20 | Y90L- 4 | 1. 5 | 265 |

| CG400X400 | 400 X400 | 100 | 10~30 | YCT160-4A | 2. 2 | 640 |

| CG600X500 | 600 X500 | 200 | 10~50 | Y112M- 4 | 4 | 1045 |

| CG700X500 | 700 X500 | 200 | 10~60 | 1100 | ||

| CG1240X980 | 1240X980 | 350 | 36~90 | Y160M- 6 | 7. 5 | 1710 |