[Introduction]: A feeding machine for short distance transportation.

[Capacity]: 15~400㎡/h

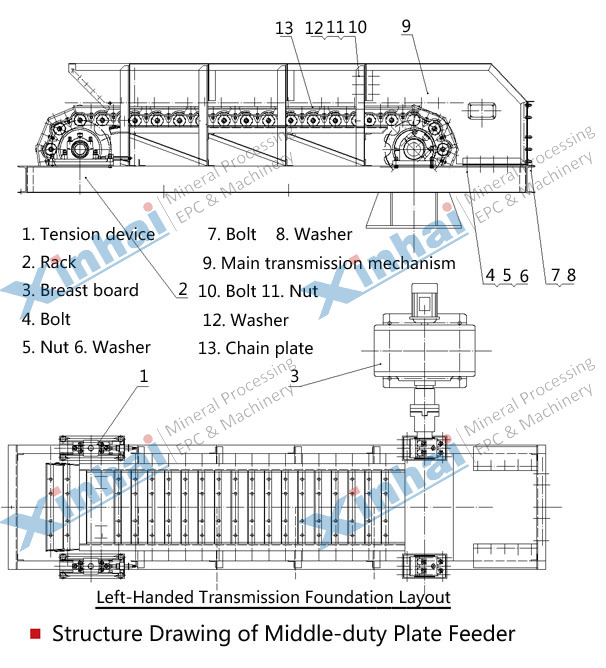

[Improvement]: It can be classified into three types, heavy-duty plate feeder, middle-duty plate feeder and light-duty plate feeder. It can be equipped in different sizes by the requirement of clients.

It can be installed both horizontally and slantly with the maximum slope angle of 12 degree;

The max feed size can reach 1000 mm.

Heavy-duty plate feeder .

The main work of the feeder is to make the motor power through reducer, arrive the connecting rod of the eccentric gear do the reciprocating motion, and also make the pawl push the ratchet to drive the rotation of the chain wheel. Thereby the intermittent motion of the chain plate will begin so as to achieve the purpose of conveying materials.

Heavy-duty plate feeder: It is suitable for short-distance transportation of the block materials with feed size of 1000 mm or less.

Medium-duty plate feeder: It is suitable for short-distance transportation of the block materials with feed size of 400 mm or less. It usually applies to transport the materials with the loose density of less than 2400 kg/m3, the block weight of less than 500 kg, and the temperature of below 400 ℃.

Light-duty plate feeder: It is suitable for short-distance transportation of the block materials with feed size of 160 mm or less. It usually applies to transport the materials with the loose density of less than 1200 kg/m3, the block weight of less than 140 kg, and the temperature of below 350 ℃.

| Model | Chain Plate | Feed Size (mm) | Capacity (m3/h) | Motor | Overall Dimension (LXWXH) (mm) | Weight (kg) | |||

| Width (mm) | Center Distance of Chain Wheel (mm) | Speed (m/s) | Model | Power (kW) | |||||

| GBH80-2.2 | 800 | 2200 | 0.01 ~0.053 | ≤300 | 15 ~91 | Y132M-4 | 7.5 | 3840X2850X1185 | 3722 |

| GBH80-3 | 3000 | XWED106-385-4 | 4 | 4868X2705X1060 | 4014 | ||||

| GBH80-4 | 4000 | Y132M-4 | 5640X2986X1185 | 5087 | |||||

| GBH80-5.8 | 5800 | 0.18 | ≤300 | 15 ~91 | XWED7.5-8215A-231 | 7.5 | 7760x2823.5x1321 | 6526.7 | |

| GBH100-1.6 | 1000 | 1600 | ≤0.15 | ≤350 | 22~131 | Y160M-6 | 3240X3026X1235 | 3981 | |

| GBH100-3 | 3000 | 4640X3114X1235 | 4548 | ||||||

| GBH100-4 | 4000 | 0.01 ~0.053 | 22~131 | XWED106-385-4 | 4 | 5648x2890x1160 | 5086 | ||

| GBH120-1.8 | 1200 | 1800 | ≤0.15 | 300-400 | 35~217 | Y160M-6 | 7.5 | 3440X3314X1235 | 3965 |

| GBH120-2.2 | 2200 | 3840X3314X1285 | 4238 | ||||||

| GBH120-2.6 | 2600 | 4240X3314X1285 | 4572 | ||||||

| GBH120-3 | 3000 | XWED7.5-8215A-273 | 4960X3150X1434 | 4886(Exclude Reducer) | |||||

| GBH120-4 | 4000 | Y160M-6 | 5640X3402.5X1285 | 6100 | |||||

| GBH120-4.5 | 4500 | XWED7.5-8215A-273 | 6460X3150X1434 | 6350.6 (Exclude Reducer) | |||||

| GBH120-6 | 6000 | 300-400 | 35~217 | XWED11-8225B-273 | 11 | 7960x3242x1434 | 8210 | ||