[Introduction]: Dry rod mill is a dry grinder machine with fine discharge.

[Capacity]: 64-180t/h

[Improvement]: Xinhai dry rod mill is developed with the international technical level, which is featured with simple structure, strong production capacity, especially suitable for the fine materials.

Uniform grinding particle size. The particle size of the dry rod mill in the open-circuit grinding operation is almost the same as that of the ball mill in the closed-circuit grinding operation;

The discharging particle size of dry rod mill can be adjusted according to the customer demand. The dry rod mill is built with the fineness control device and screening device, which avoids over-grinding and prevents the unqualified products from mixing in the finished product;

The particle size characteristics of dry rod mill are related to the grinding conditions. When the steel rod collides with the ore, the coarse material will be ground first, and then the smaller material, thus reducing the over-grinding problem;

When the steel rod rises along with the lining plate, the fine particle sizes pass through the rod gap, which is also conducive to crushing coarse particle sizes, making the coarse particle sizes concentrate in the grinding location of the steel rod. Therefore, the product of the dry rod mill is more uniform.

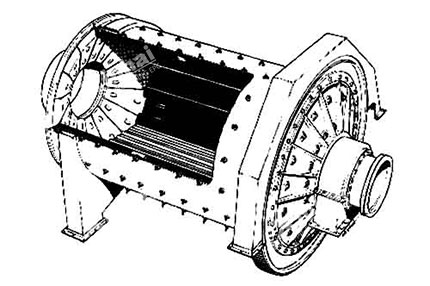

The working principle of the dry rod mill is the same as that of the wet rod mill. The gearing-down of a electrical machinery and peripheral gear drives the cylinder body of the dry rod mill rotates. The appropriate steel rod is installed in the cylinder body of a dry rod mill as the grinding medium. Under the action of centrifugal force and friction force, the grinding medium is lifted to a certain height and dropped down. The materials are continuously sent into the cylinder body of a dry rod mill from the feeding port, then crushed by the moving grinding medium, and discharged out of the dry rod mill by the overflow and the continuous feeding.

| Models | Cylinder Size(mm) | Cylinder Speed (r/min) | Feed Particle Size (mm) | Discharging Particle Size(mm) | Processing Capacity(t/h) | Power(kw) | Power(t) | |

| Diameter | Length | |||||||

| MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |